Products

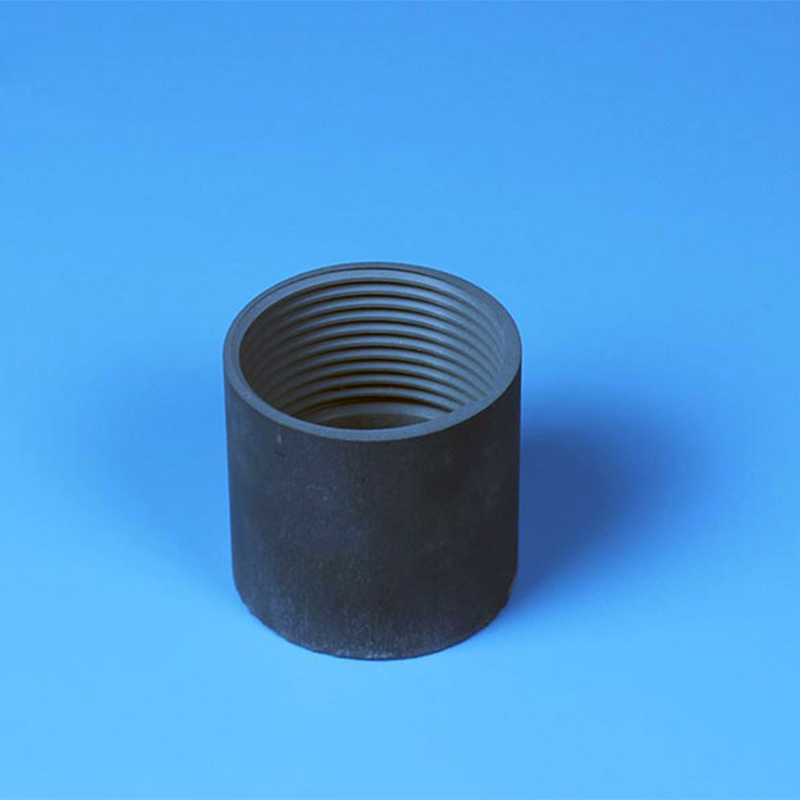

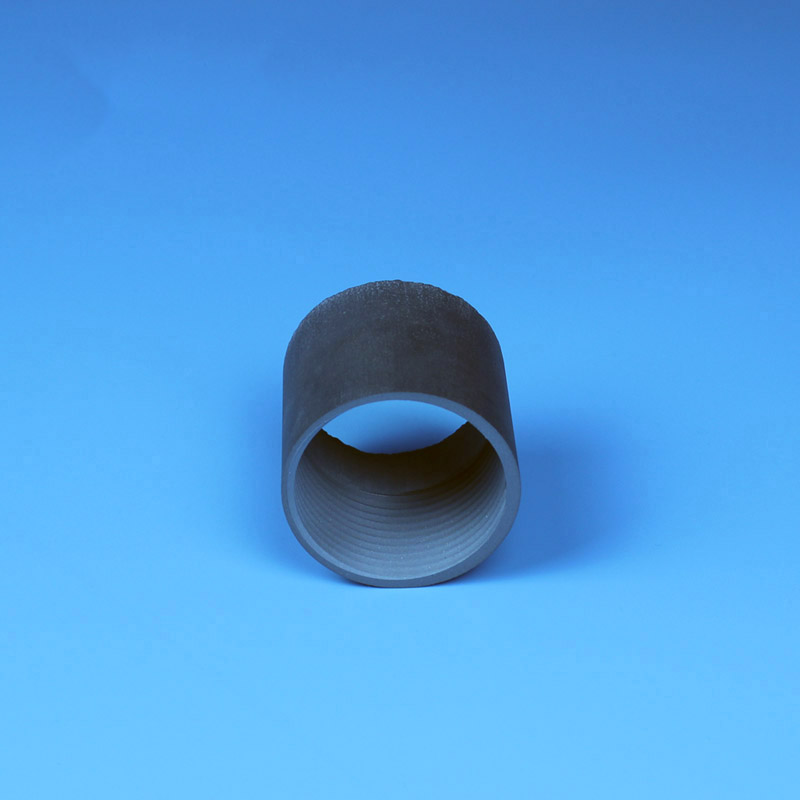

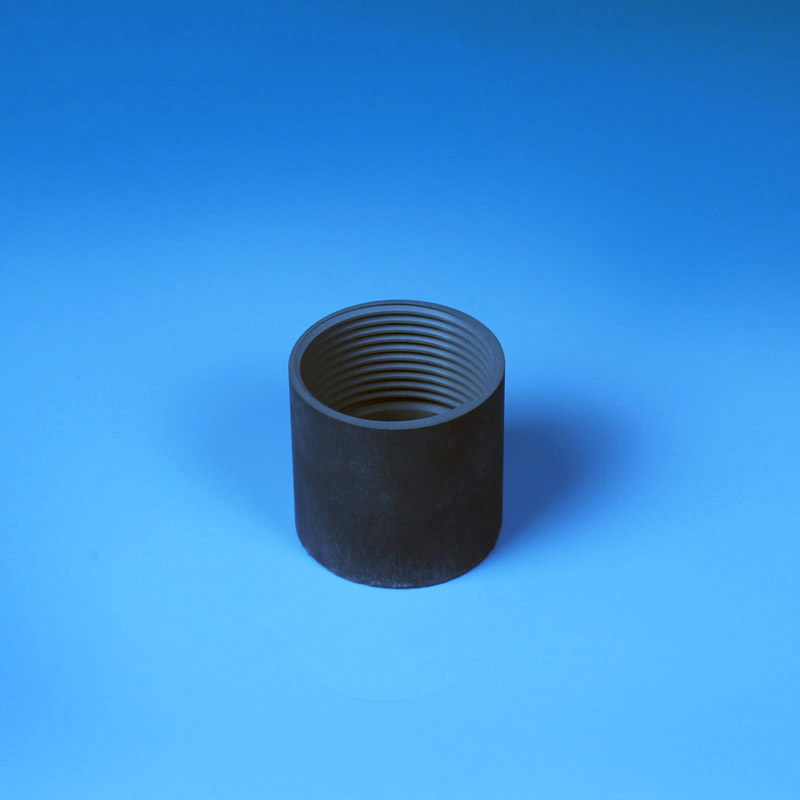

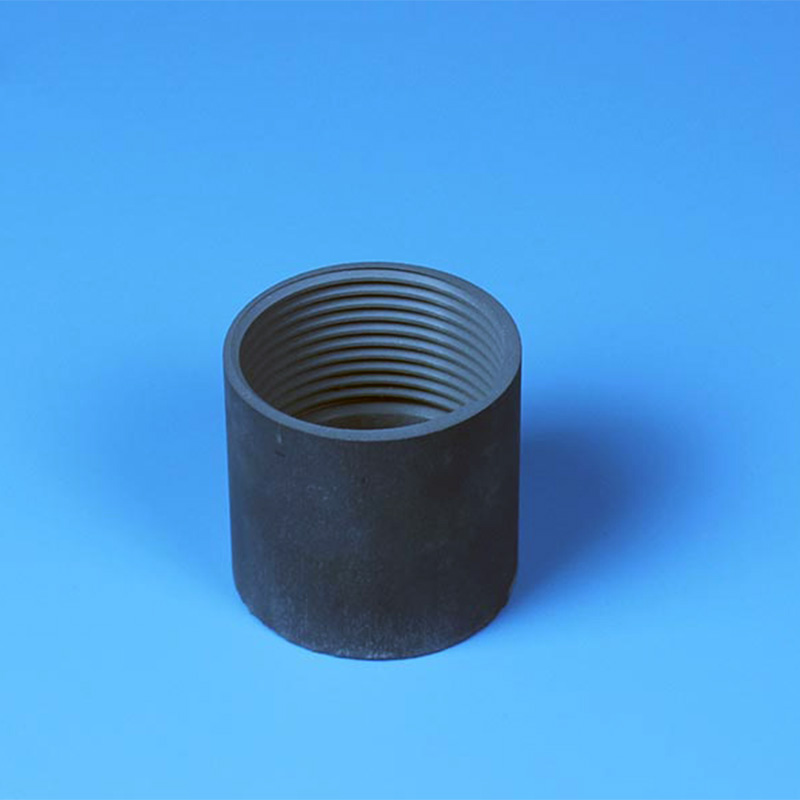

Silicon carbide internal thread ceramics tube

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

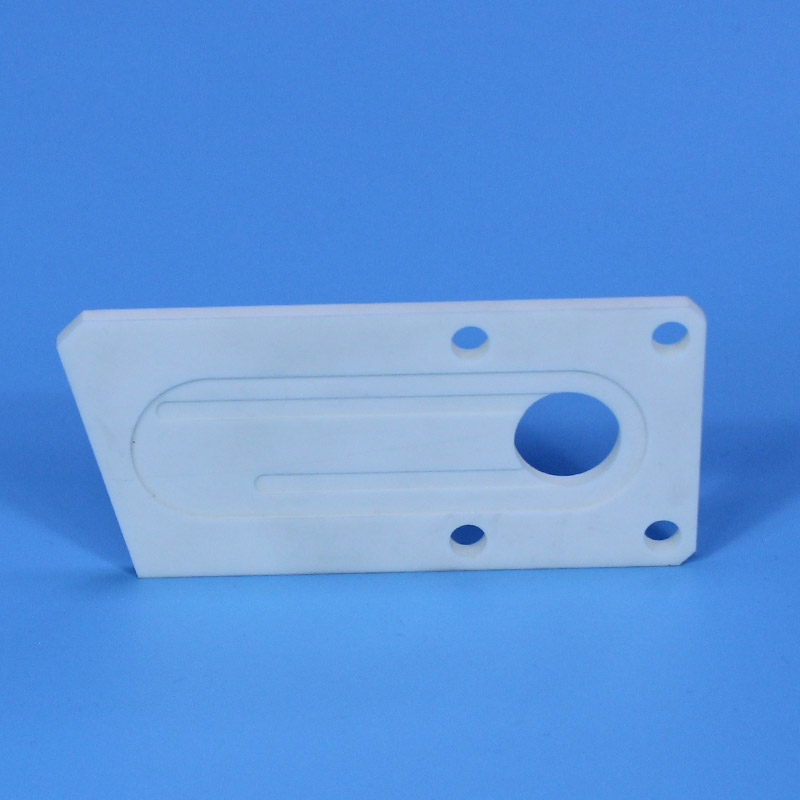

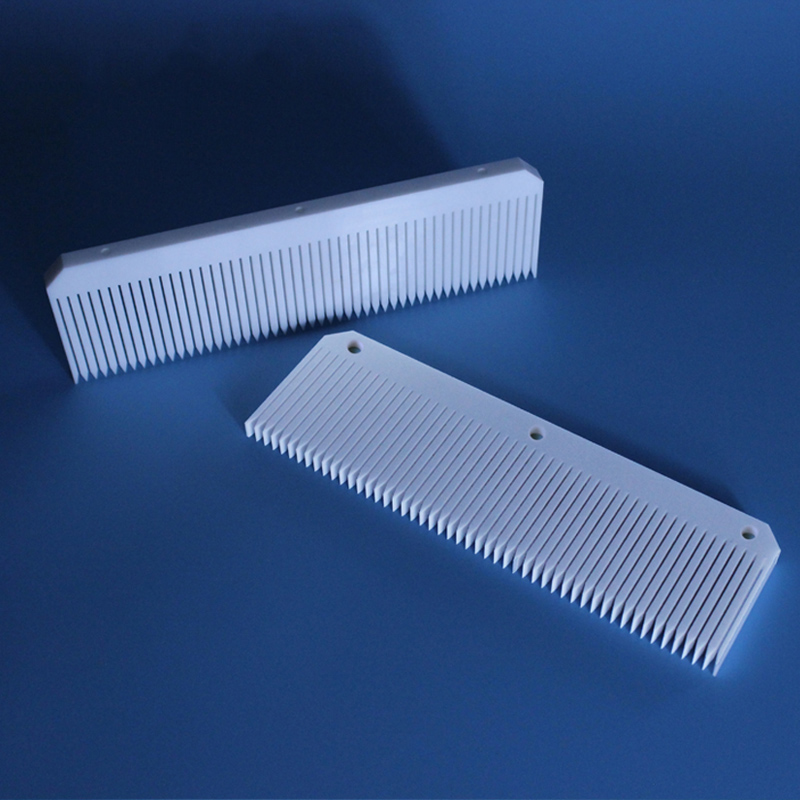

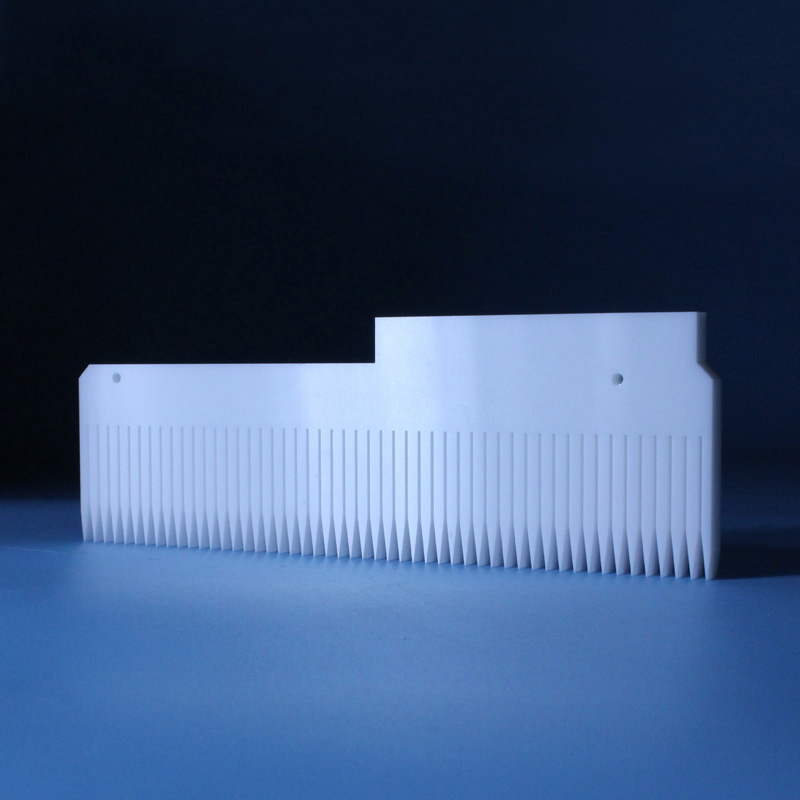

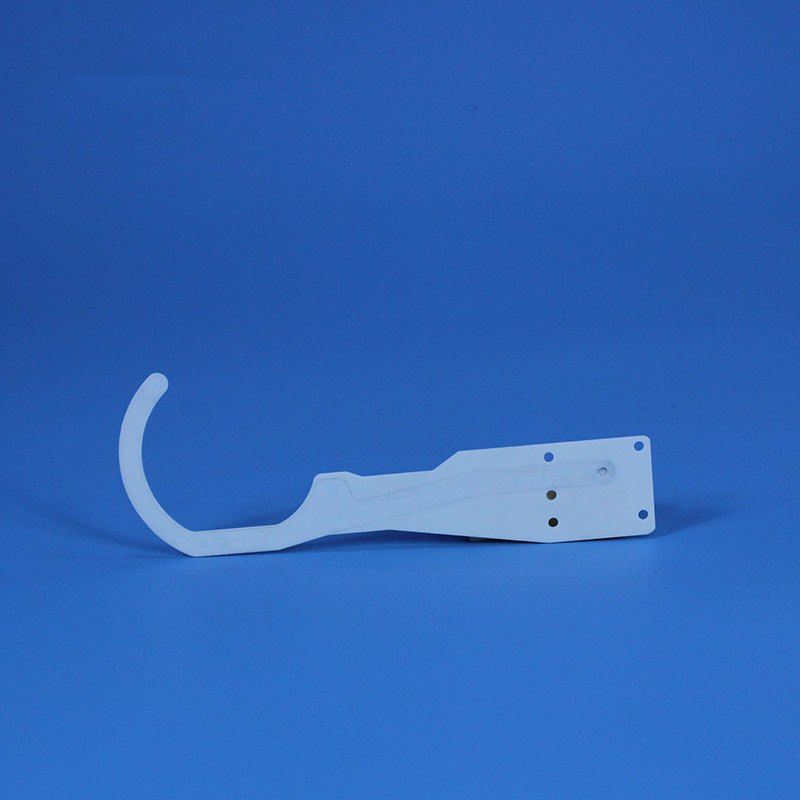

Product Details

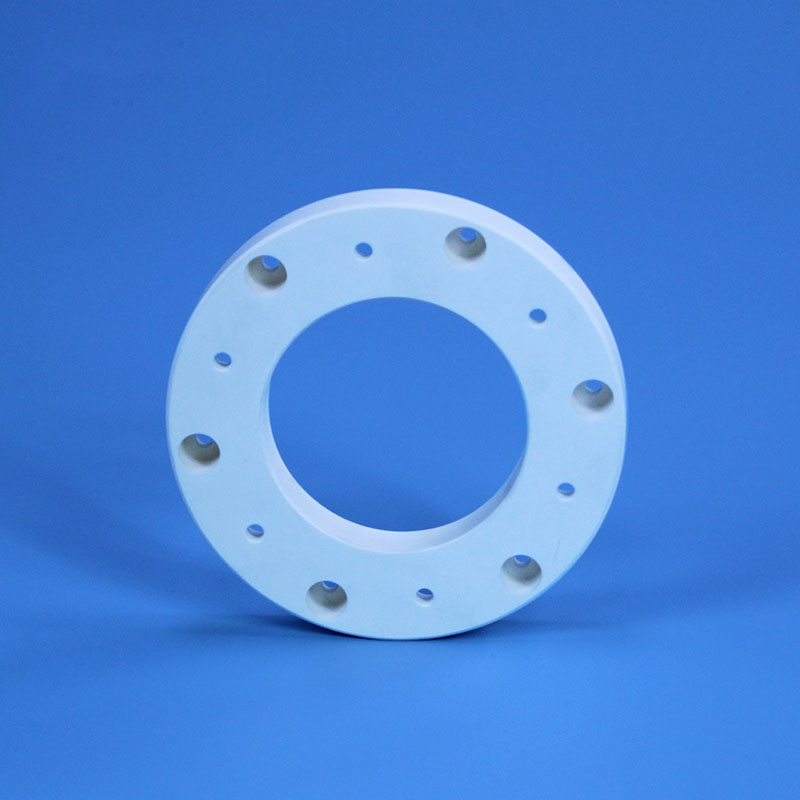

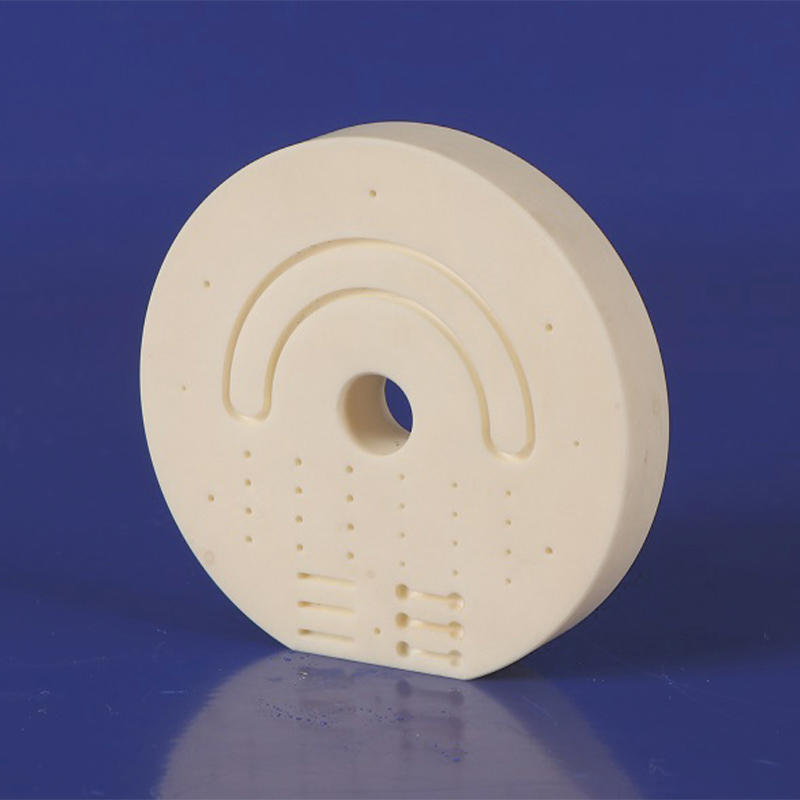

Silicon carbide internal thread ceramic tube

The application of silicon carbide ceramics in many industrial fields shows its excellent performance, which has attracted widespread attention. Silicon carbide ceramics are a large family in the field of inorganic non-metallic materials, and their tentacles extend almost all industrial fields. Silicon carbide ceramic is an ideal material for the manufacture of sealing rings. When it is paired with graphite materials, its friction coefficient is smaller than that of alumina ceramics and cemented carbide, and it has good self-lubricating properties. The service life and the reliability of the work are improved, especially in the case of conveying strong acid and alkali.

Silicon carbide is a man-made material. It was only after the artificial synthesis of silicon carbide that it was confirmed that silicon carbide occasionally existed in meteorites and on the crust [2]. There are many preparation methods of silicon carbide powder, including the oldest Acheson synthesis method (Acheson), as well as the laser method and organic precursor method developed in the past ten years. The following is a typical Acheson silicon carbide synthesis method. . Silicon carbide ceramics have high mechanical strength, good rigidity and high mechanical strength, which can effectively prevent material deformation, which is very important. The mechanical strength of silicon carbide is higher than that of corundum. For example, the compressive strength of silicon carbide is 224MPa, and corundum is only 75.7MPa; the flexural strength of silicon carbide is 15.5MPa, while that of corundum is 8.72MPa.

The hardness of silicon carbide is quite high, according to the Mohs notch hardness of 9.2~9.6, second only to diamond and boron carbide, higher than corundum and ranks among the top of ordinary abrasives. Compared with metal steel materials, it not only has high hardness, but also has a small friction coefficient in a non-lubricated state, relatively small friction force, small surface roughness, and good wear resistance. In addition, it has strong impact resistance to external substances, which improves the bearing capacity of the surface.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Boron carbide ceramic B4C