Products

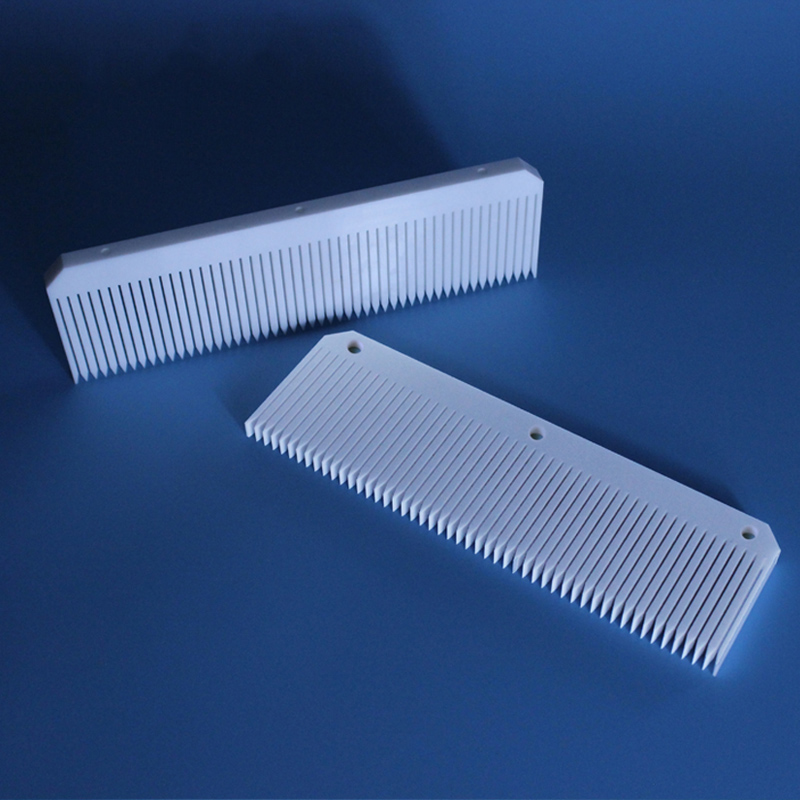

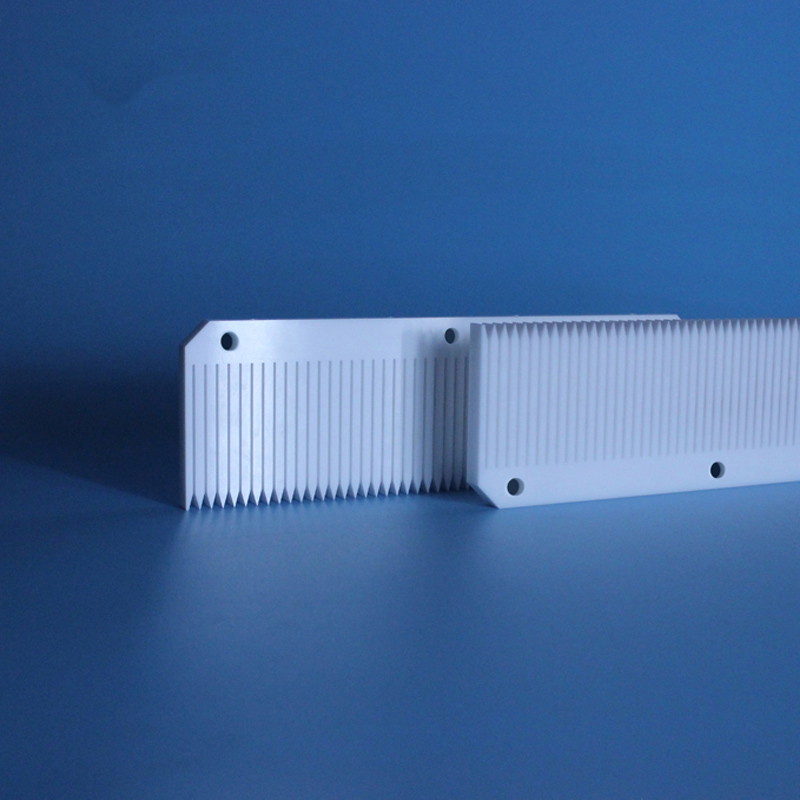

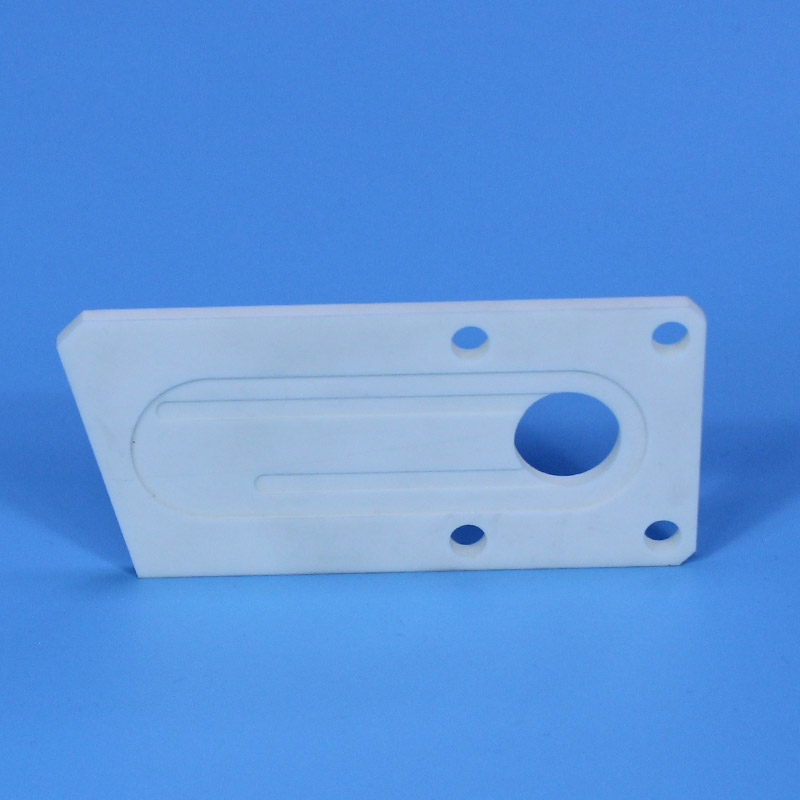

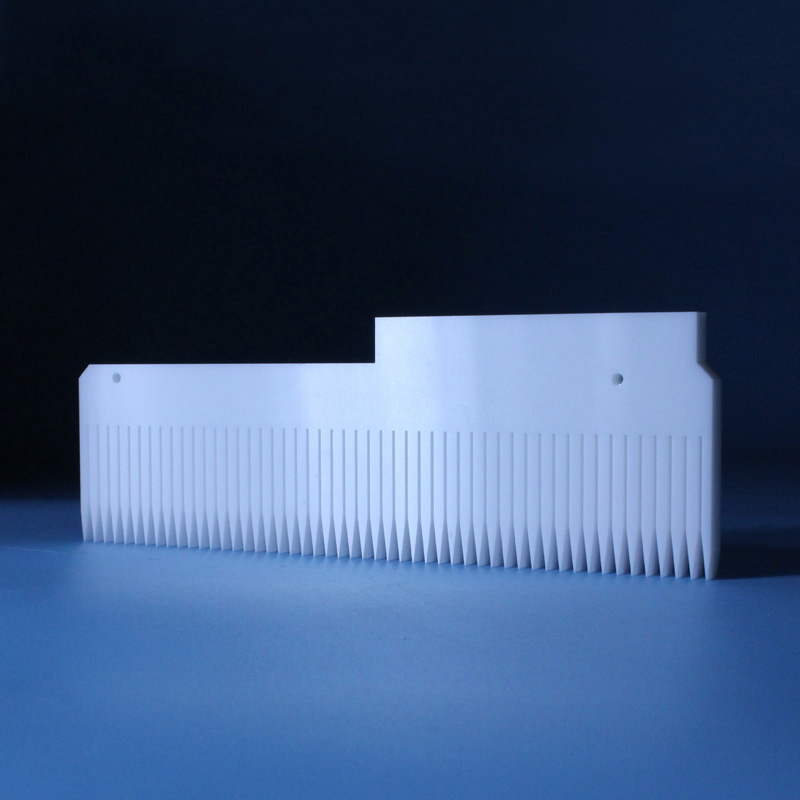

Zirconia ceramic top comb

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

Ceramic top gear is an important component used in photovoltaic production equipment, and the demand is relatively large. Usually a photovoltaic equipment production line needs to use many of these products. Ceramic top teeth are generally made of zirconia, so many people also call it zirconia ceramic top teeth. The processing principle of ceramic top gear is very simple, that is, the shape that people want is processed by the grinding wheel of the grinder. Although the principle is relatively simple, the requirements for the technical level of the operators are relatively high. Generally, it takes more than a few years of masters to process this product. Huamin Ceramics has relatively rich experience in the field of ceramic top gear processing, and supplies many photovoltaic equipment manufacturers at home and abroad.

Precautions for the processing of ceramic top comb

When processing zirconia ceramic top comb, attention should be paid to the precision between the teeth and the edge collapse. Generally, a grinding machine is used to process the tooth profile first, and then a ceramic special CNC machine tool is used to process the hole or thread on the top tooth. According to the size and quantity of the tooth profile, the processing time also has a relatively large difference.

Ceramic top teeth are also called ceramic side combs and ceramic vertical combs. It is a main component of the straight combing machine. In the combing cylinder, the top comb is raised when combing, and the top comb is lowered when the beard bundle is separated, and the tail of the fiber beard bundle that has been combed by the cylinder is combed. The location should be close to the extraction skin plate (cover roller) in the extraction stage, and the spacing should be 0.5~1mm to ensure that the part of the fiber whisker that is not combed by the cylinder can be combed by the top comb.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Zirconia ceramic side comb