Products

Boron carbide ceramic B4C

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

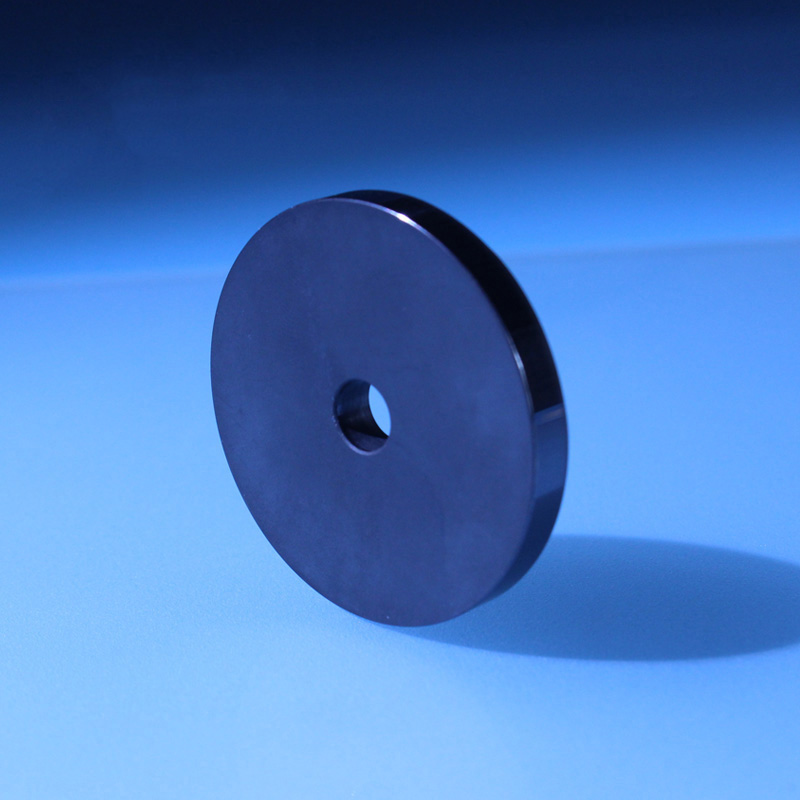

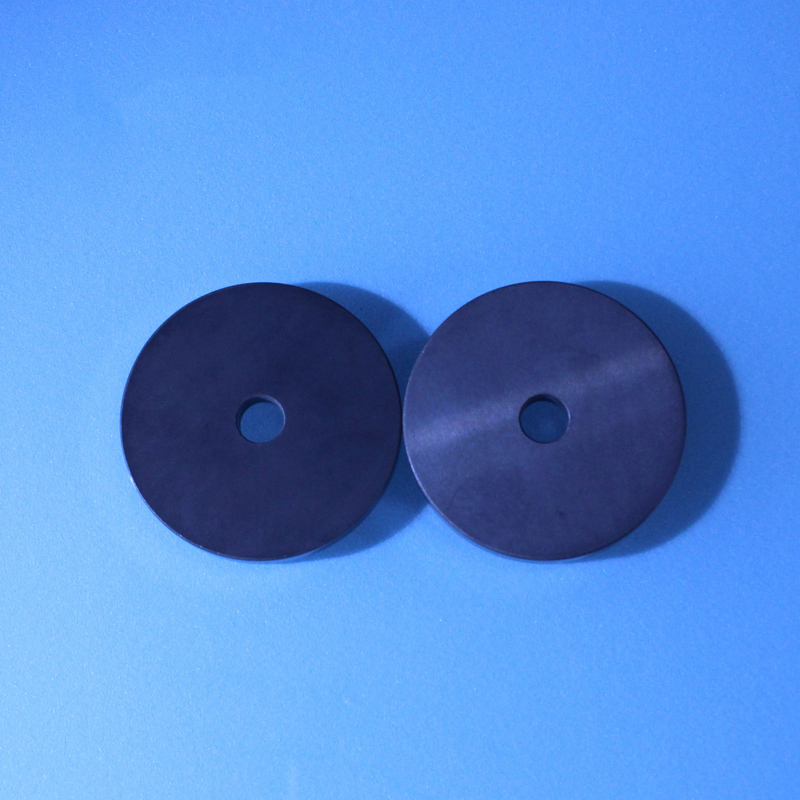

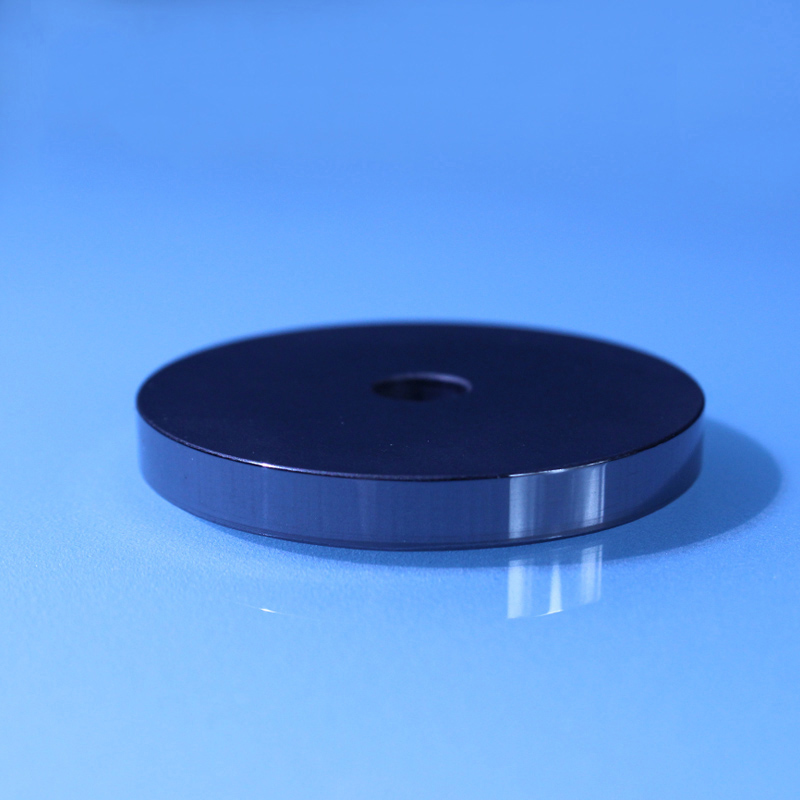

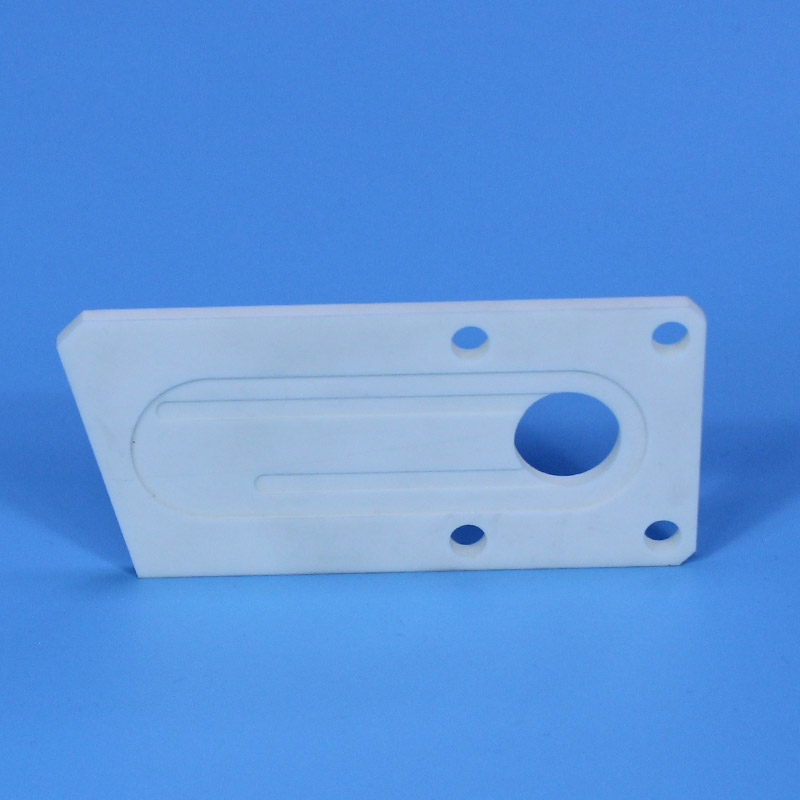

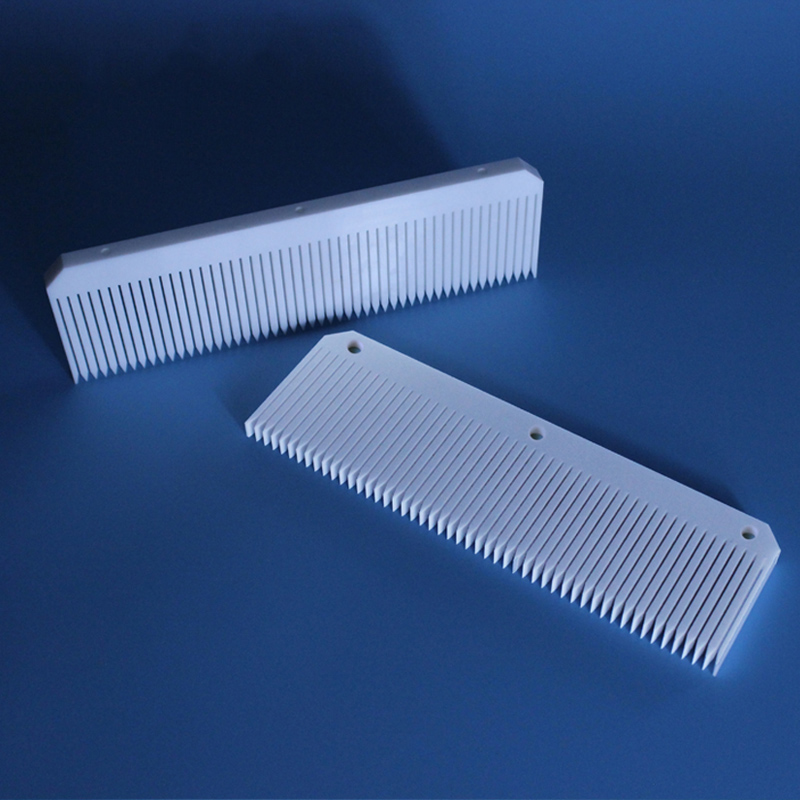

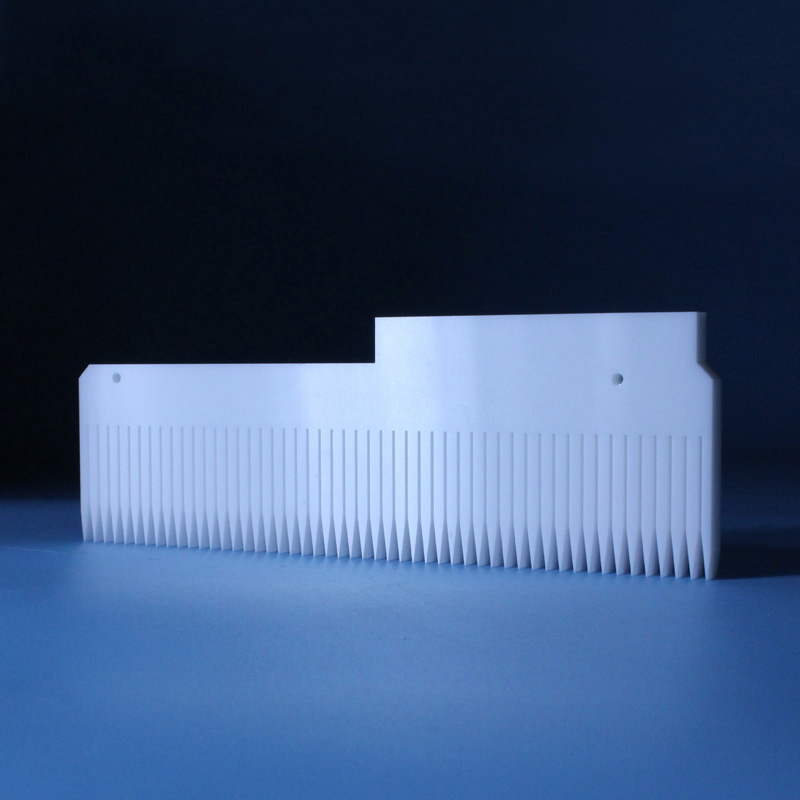

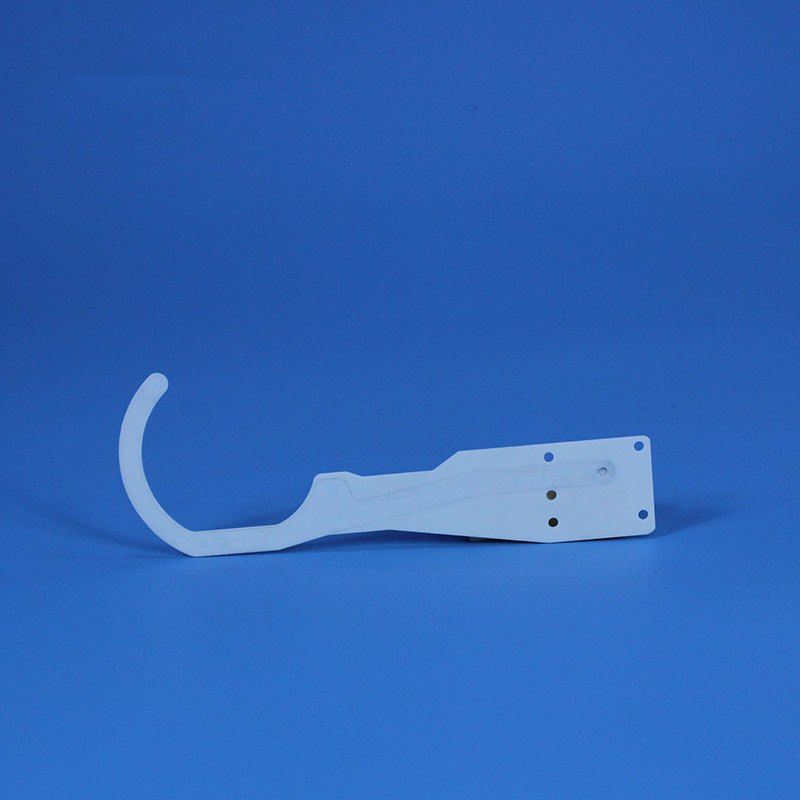

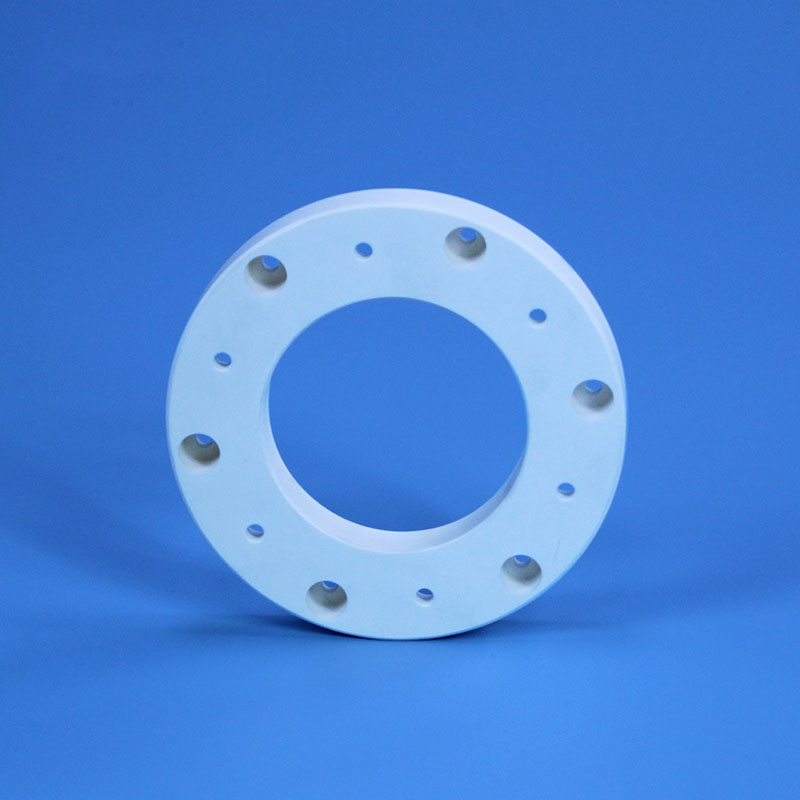

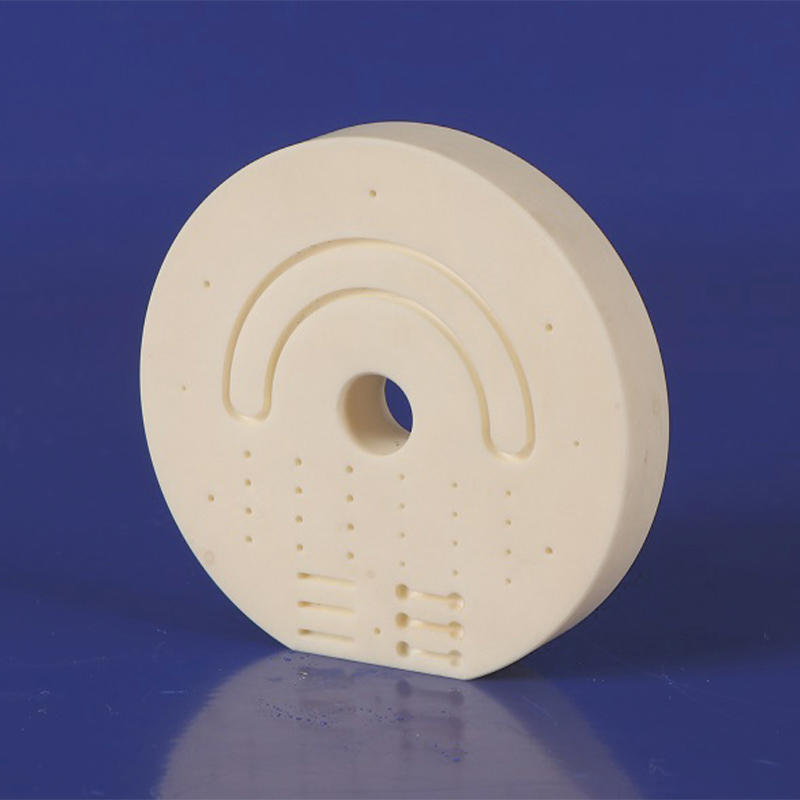

Boron carbide ceramic B4C

This product is made of hot-pressed boron carbide ceramics through drilling, plane grinding, polishing and other processes. The roughness of the polishing part is Ra0.03μm, the roughness of the plane grinding part is Ra0.6μm, and the aperture is 3mm. We use advanced processing technology and equipment to effectively prevent the occurrence of chipping at the edge of the product.

Boron Carbide, Silicon Carbide Powders and Compounds

Boron carbide (B4C) powder from Advanced Abrasives has a Mohs hardness of 9.5, which is almost as hard as cubic boron nitride (cBN), making it a low-cost alternative to diamond and cBN. The tightly controlled grading and particle shape of this powder results in high stock removal rates and a uniform finish.

Also available as a boron carbide compound, the powder is present in a grease-based carrier. Boron carbide powders and compounds are available in a variety of grit sizes, from F10/30 to F1500, for precision grinding and polishing of many engineered materials.

Advanced Abrasives' black silicon carbide powders are water classified to precise specifications. Controlled grading and precise particle shape provide a uniform finish and high stock removal rates. It offers a wide range of grit sizes from F80/100 to F1200 for pressure blasting, bonded and coated abrasive products, quartz sawing, and precision grinding and polishing.

PremaSol silicon carbide compounds are made from silicon carbide powder in a variety of base carriers (general purpose, oil-based or water-based). Tightly controlled grading and particle shape ensure high stock removal rates and a uniform finish. Available in a wide range of abrasive sizes from 1 to 80µm, it is typically used for precision grinding of ceramic and metal seal faces.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Aluminum Nitride Ceramics Substrate