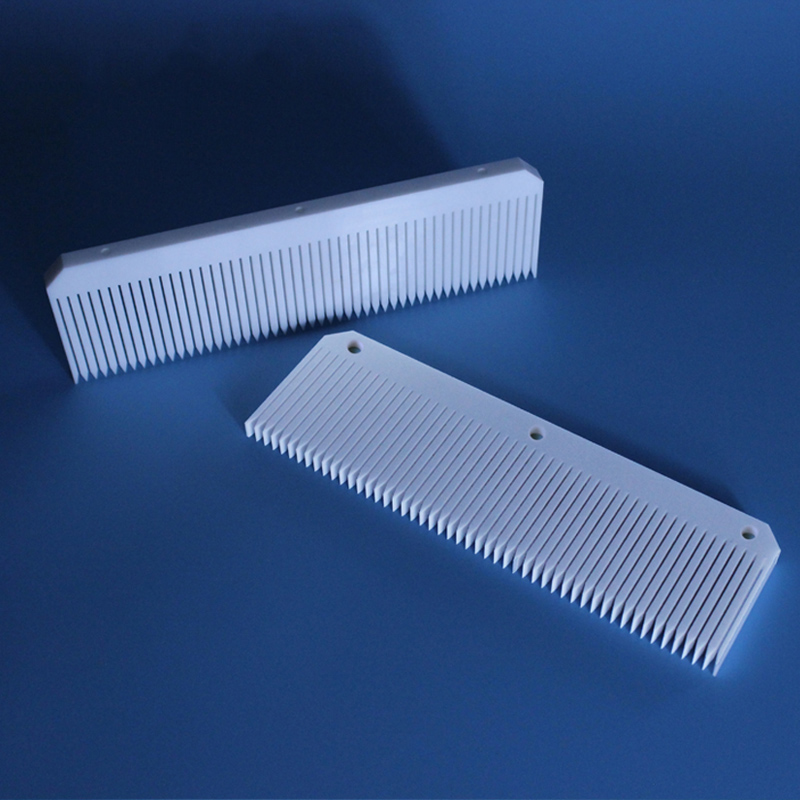

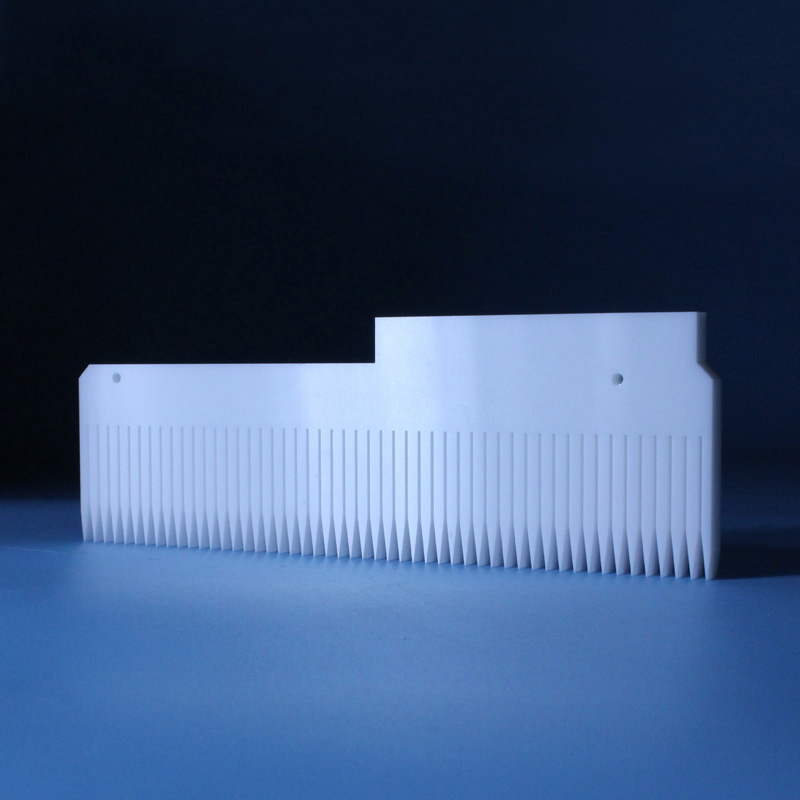

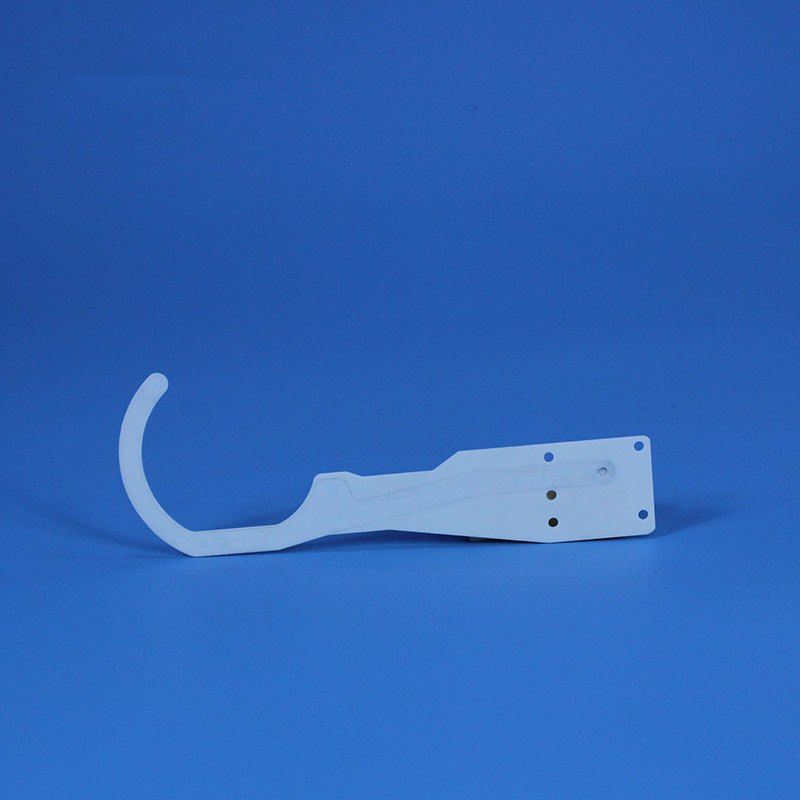

Products

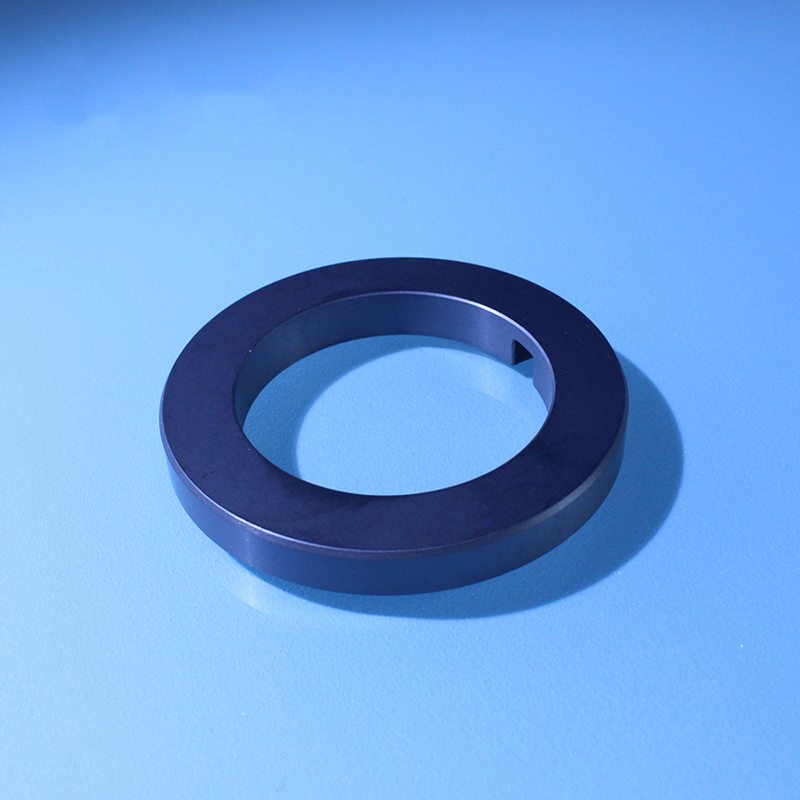

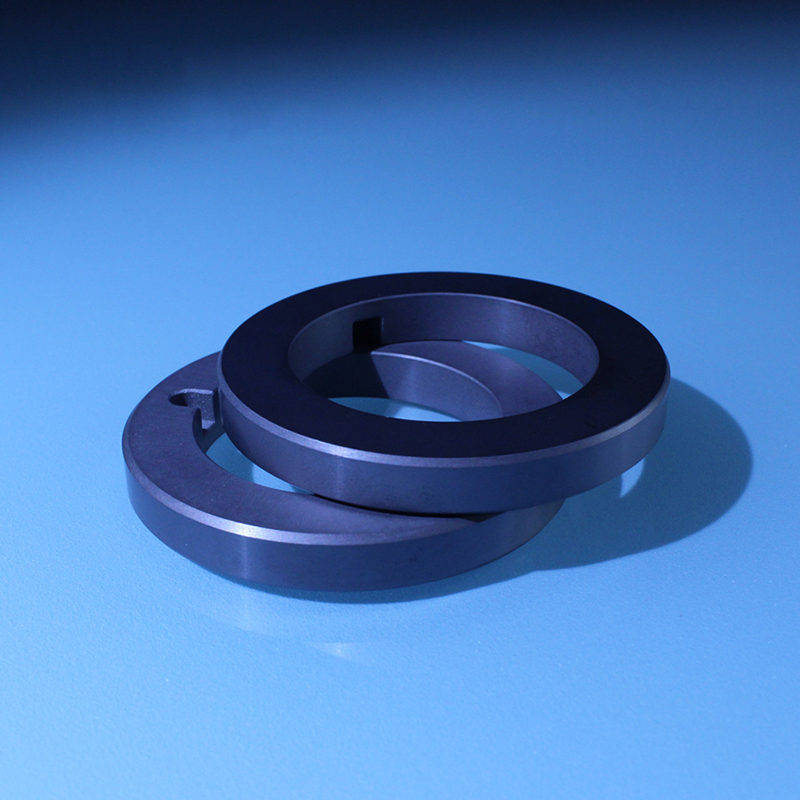

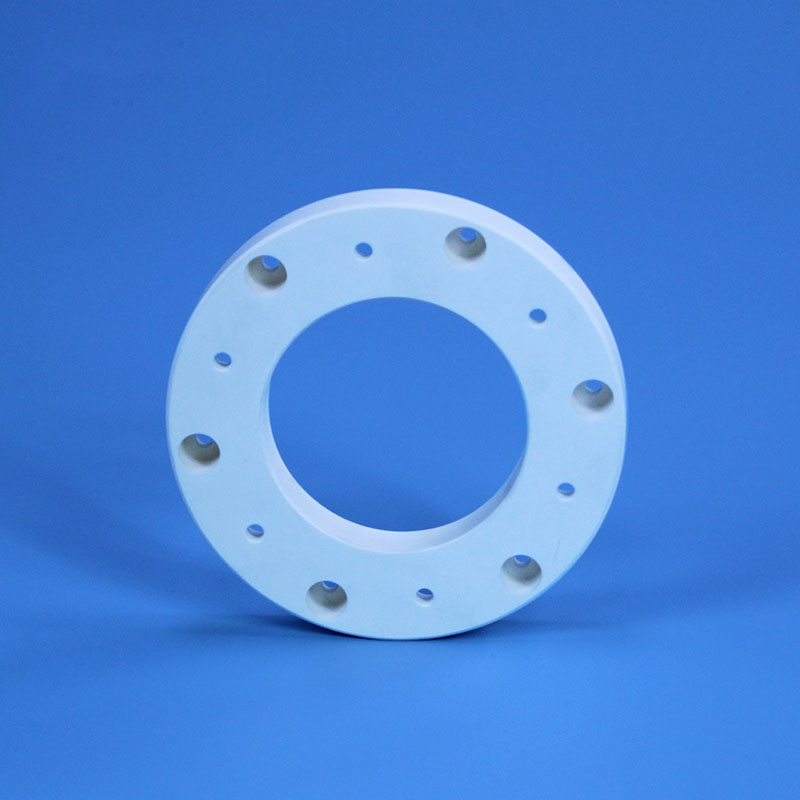

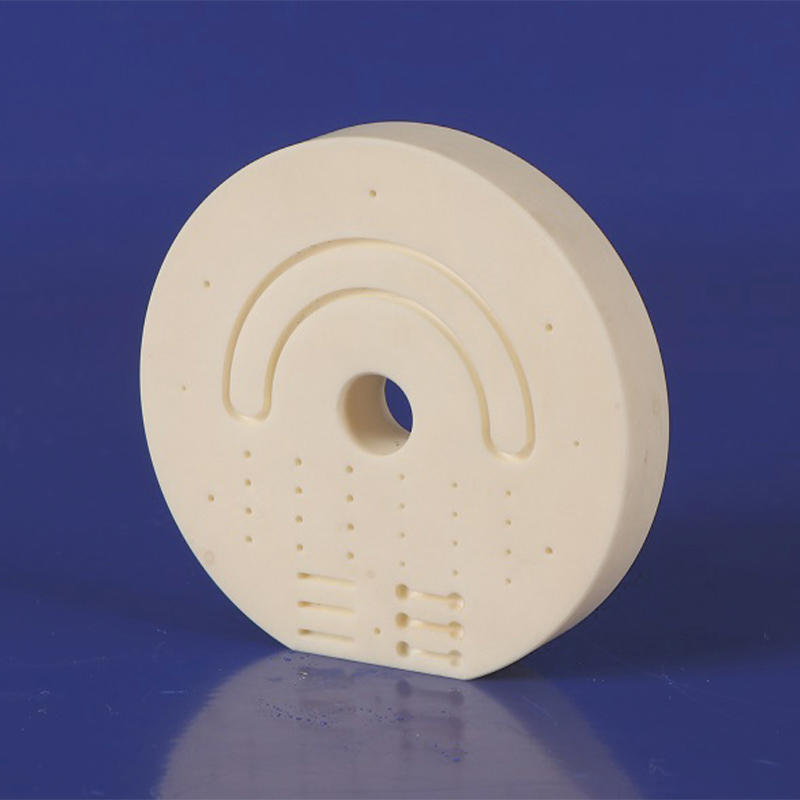

Silicon nitride ceramic seal ring

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

Silicon Nitride Ceramic Seal Ring

Silicon nitride ceramic is an inorganic material ceramic that does not shrink during sintering. Silicon nitride is very strong, especially hot-pressed silicon nitride, which is one of the hardest substances in the world. It has the properties of high strength, low density and high temperature resistance.

Ceramic sealing rings are materials and components that prevent fluid or solid particles from missing between adjacent critical surfaces and prevent external impurities or residues, such as invisible dust and moisture, from entering the mechanical parts.

Precautions for Using Silicon Nitride Ceramic Seal Rings

1. Select the appropriate sealing material and hydraulic oil, and adapt to the temperature environment and oil compatibility during work.

2. The concentricity of the geometrical position of the parts sliding relative to the seal, good material quality and finer surface roughness can prolong the service life.

3. The oil seal used for hydraulic pump and motor journal not only requires the roughness of the sliding surface to be within 0.25m of Ra, but also requires hard chrome plating on the surface, and the lip diameter of the oil seal needs to be appropriate according to the specific conditions of use. Adjustment. The rocking spring force makes it reasonably tight, and a mounting sleeve or spacer is used to protect the seal ring during installation so that the lip doesn't curl or twist, causing the spring to slip out.

4. The inner surface of the cylinder barrel is usually processed by rolling, which not only improves the surface roughness, but also cold hardens the surface, which is beneficial to prolong the service life of the sealing ring. In addition, the use pressure, the length and type of sliding surface have a great influence on the service life. Therefore, the timing of the "check" should be determined based on these conditions.

5. The sealing surface is required to be in a good lubrication state to prevent the intrusion of dirt. The use of oil up to the required cleanliness and the correct installation method are also necessary conditions.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

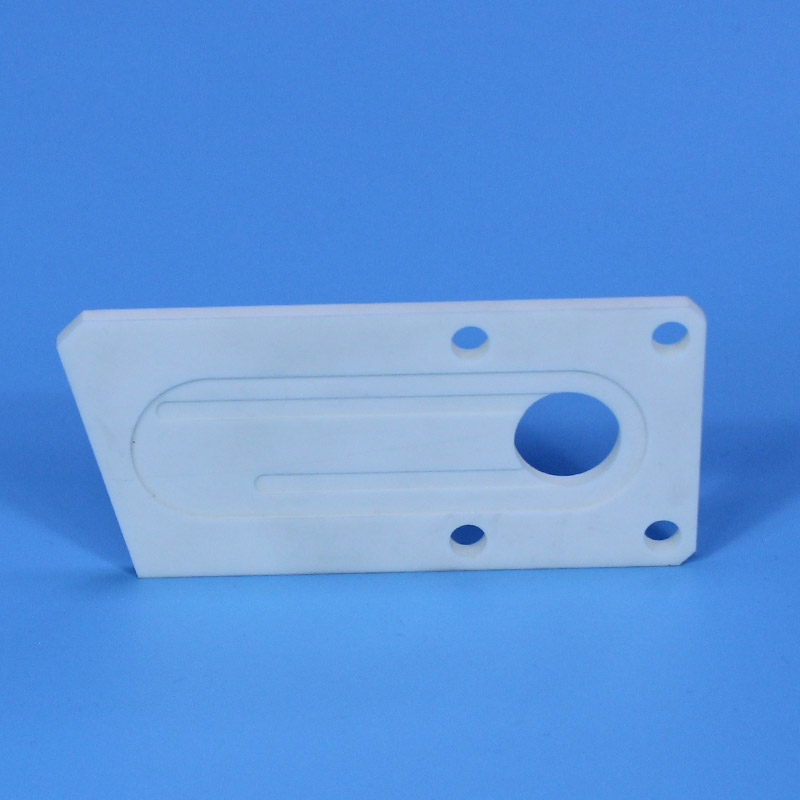

Previous: Alumina Ceramic Suction Tablets

Next: No