Products

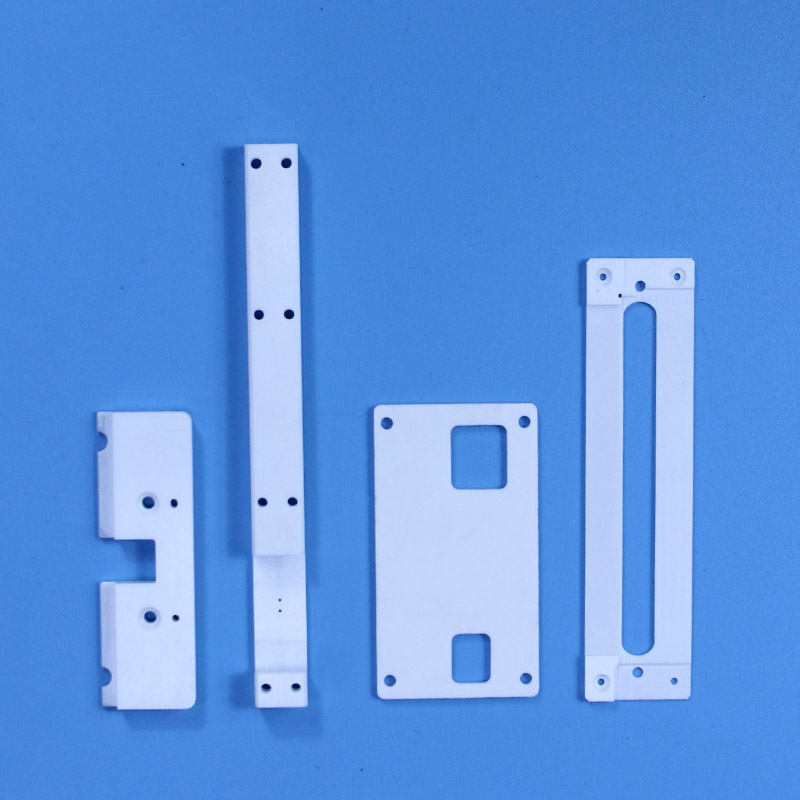

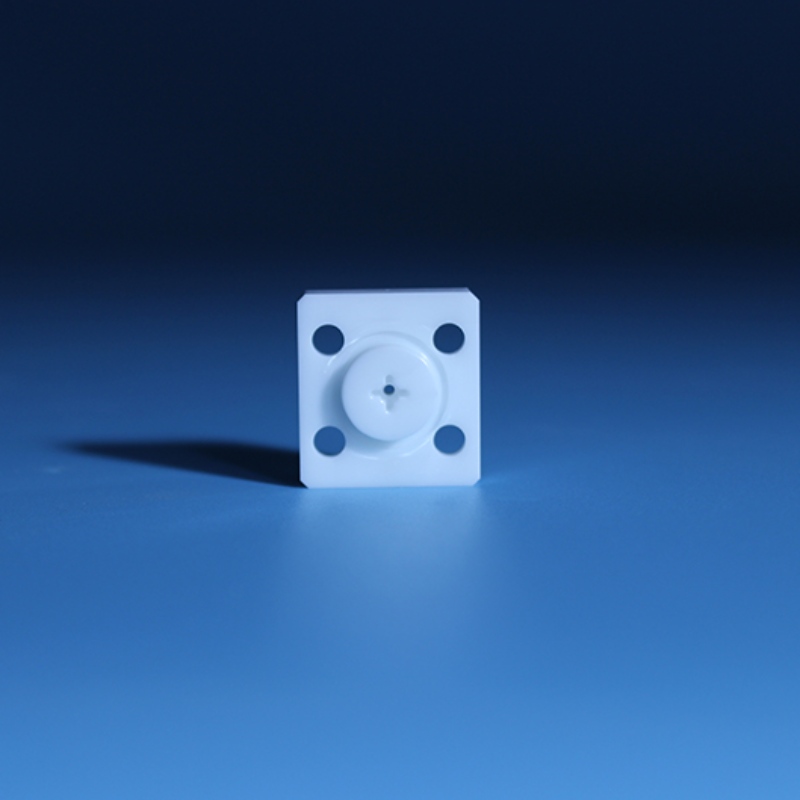

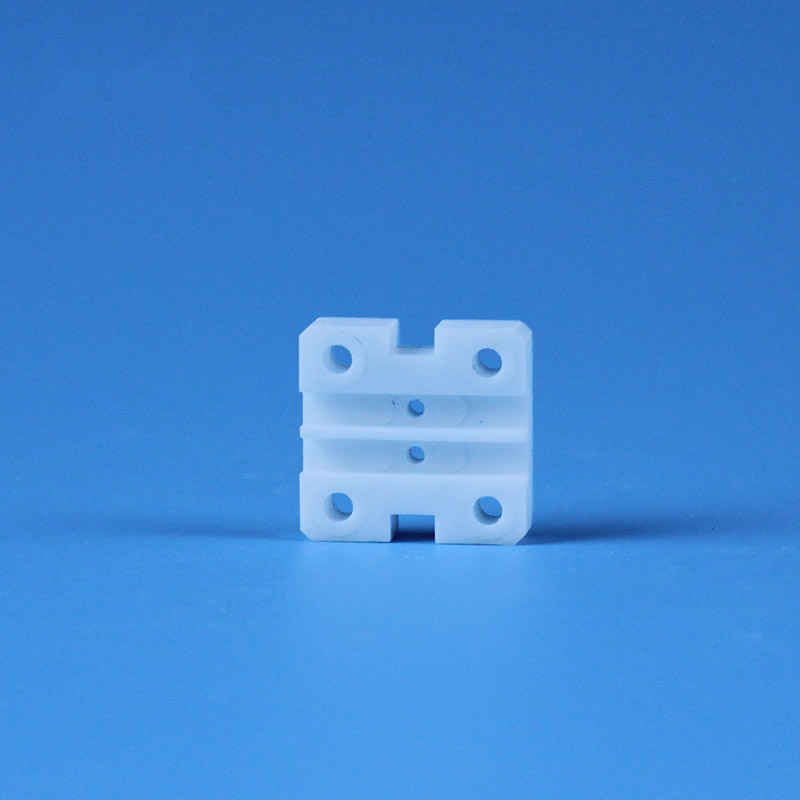

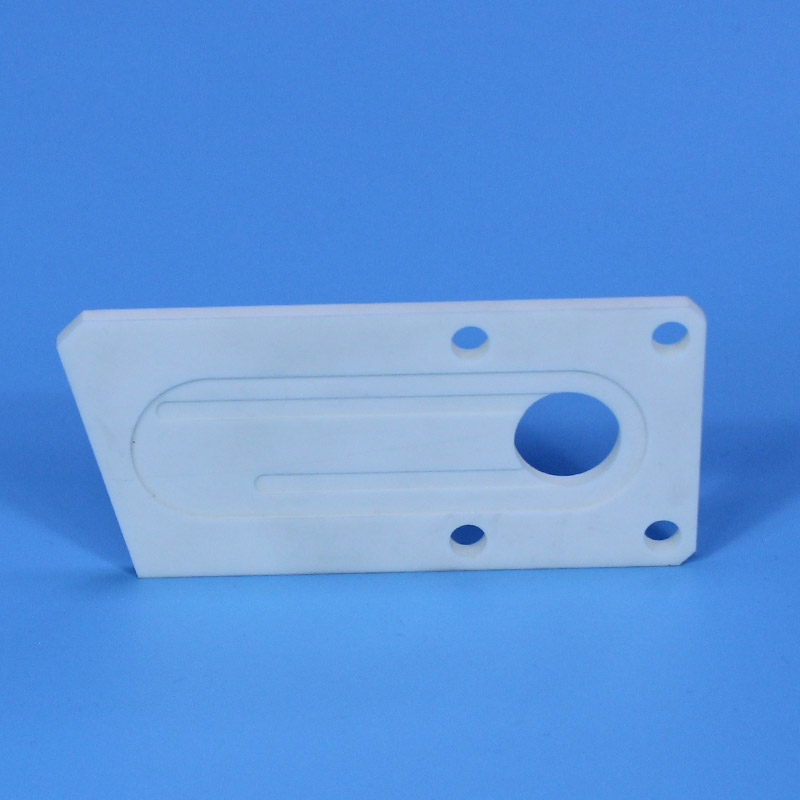

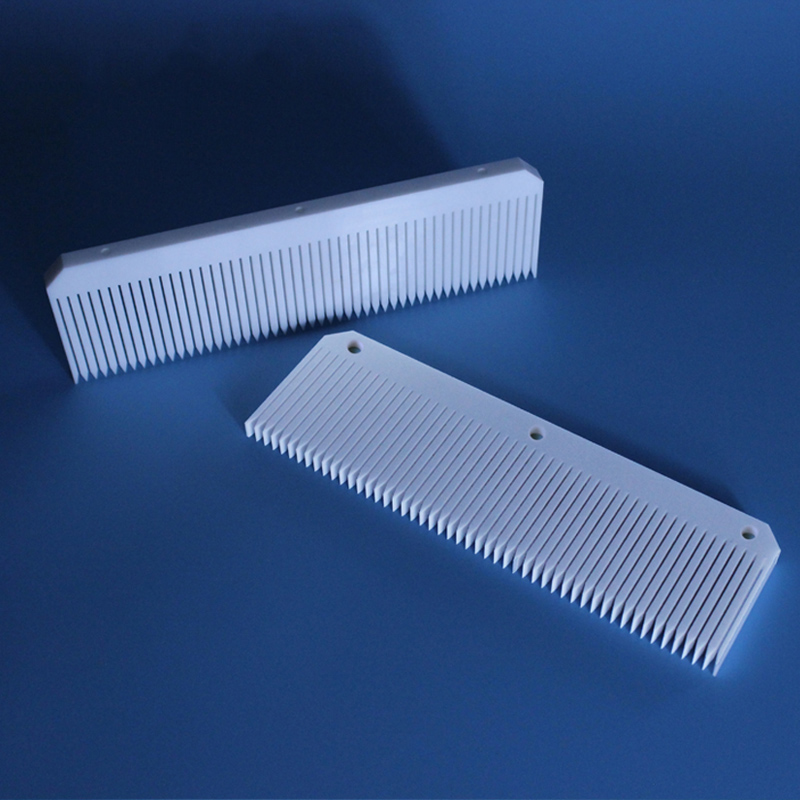

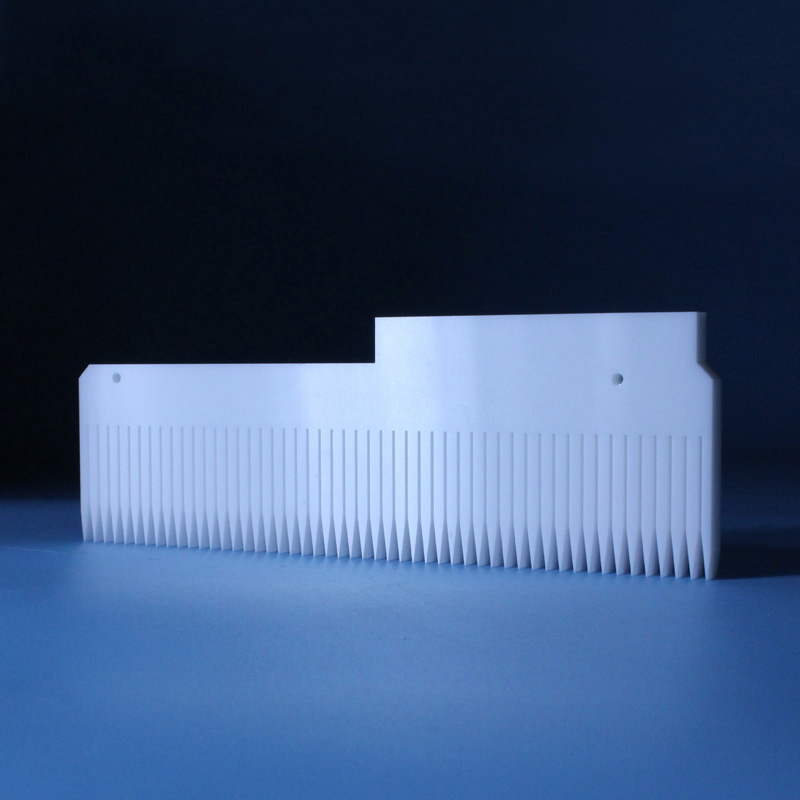

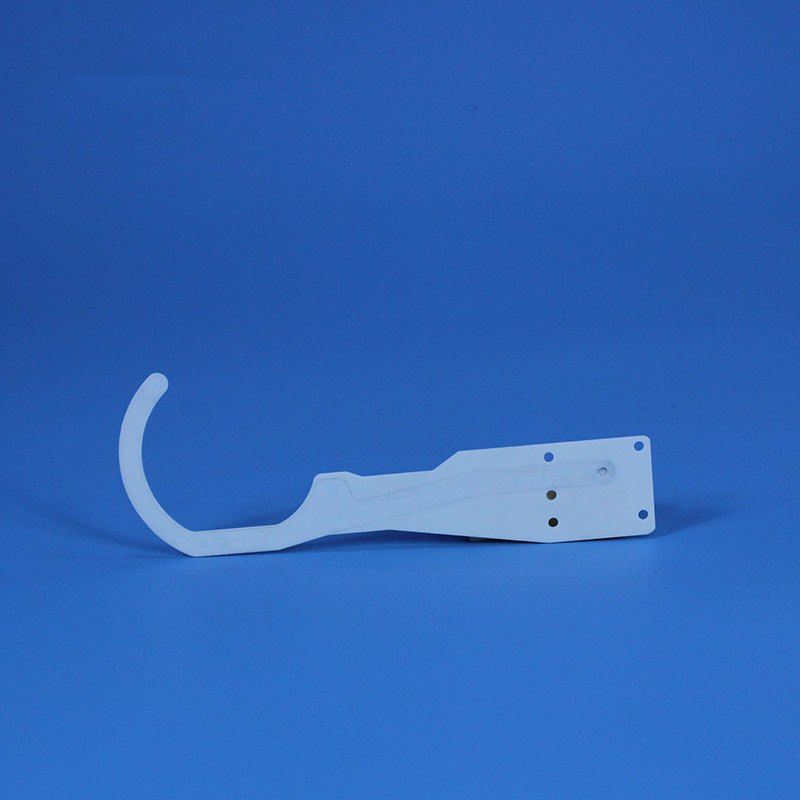

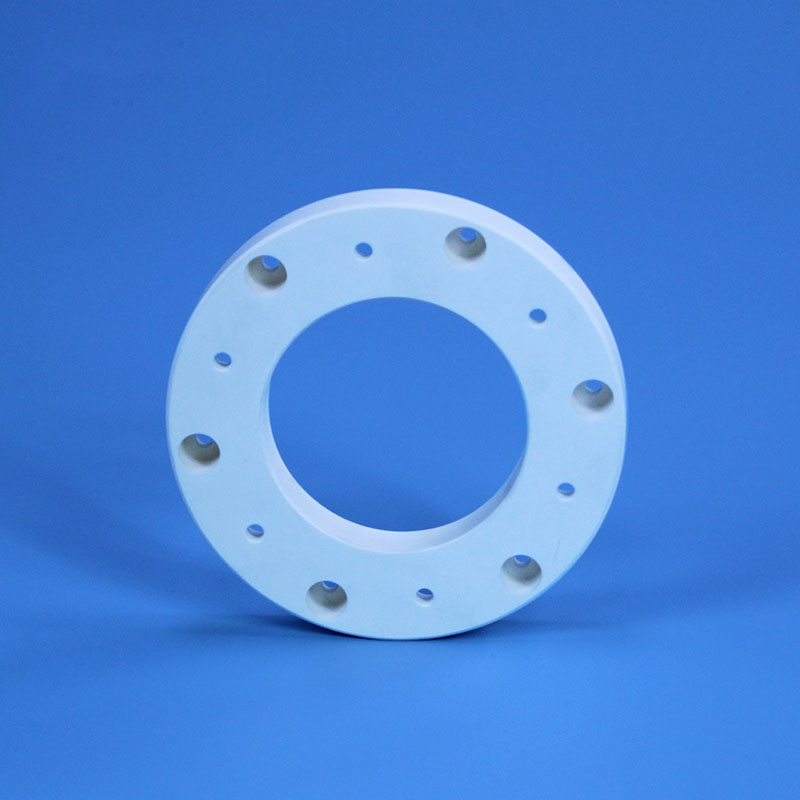

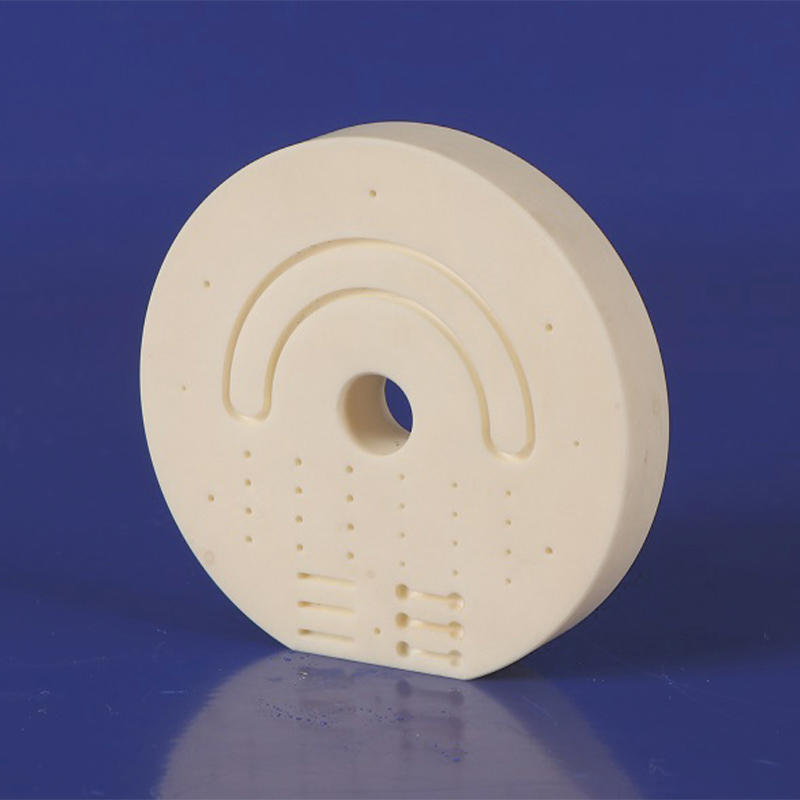

Zirconia Ceramic Structural Parts

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

Zirconia ceramic structural member:

Zirconia ceramic structural member parts are also called engineering ceramics and fine ceramics. It is a non-metallic material with high temperature resistance, wear resistance and corrosion resistance. Its melting point is as high as Celsius. It is one of the materials with good fire resistance in nature. At the same time, it can display special functions such as electricity, magnetism, light and sound under certain conditions. Therefore, it can be used in many fields and is a product worthy of our trust.

Zirconia ceramics, namely ZrO2 ceramics (Zirconia Ceramic) have high melting point and boiling point, high hardness, excellent wear resistance, normal temperature insulator, and high temperature conductivity. Pure ZrO2 is white, yellow or gray when it contains impurities, and generally contains HfO2, which is not easy to separate. As the most important type of advanced ceramics, zirconia ceramic materials are very important basic materials for the development of modern high-tech industries. With the advent of the 5G era of mobile phones, zirconia ceramics have become an industry due to their warm touch, scratch resistance, almost no signal shielding, and excellent heat dissipation performance. Hot spots, so that more people pay attention to this ceramic material.

Zirconia ceramic rods are also called ivory white. White is the most widely used of all ceramic rods. The ceramic rod is made of high-strength zirconia raw material and made of special ceramic materials. It has excellent properties such as drop resistance, wear resistance, super hard, high temperature resistance (fire resistance), super corrosion resistance, no rust, oxidation resistance, insulation, and self-lubricating! Zirconia special ceramic materials are widely used in instrumentation, medical equipment, clocks, abrasive tools, energy and electricity, construction, machinery hardware, automobiles, military industry, aerospace and other fields.

Huamin Ceramics specializes in manufacturing various types of precision ceramic structural parts. We provide labor and materials services to make you more worry-free.

Because zirconia wear-resistant ceramics have the advantages of high hardness, high strength, good wear resistance, long service life, heat shock resistance, etc., they can withstand various tests in harsh working environments, so they are often used for grinding and polishing materials, resistant to Grinding coatings, pipelines or equipment linings, equipment structural parts and other fields. There are three crystal forms of zirconia ceramics, namely monoclinic zirconia, tetragonal zirconia and cubic zirconia, and these three forms will change with the temperature. Zirconia ceramics is a commonly used processing technology in surface grinding and processing. In order to meet the needs of consumers, professional zirconia ceramic grinders are used to grind and polish zirconia ceramic products.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Zirconia Ceramic Injection Parts