Products

Zirconia Ceramic Injection Parts

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

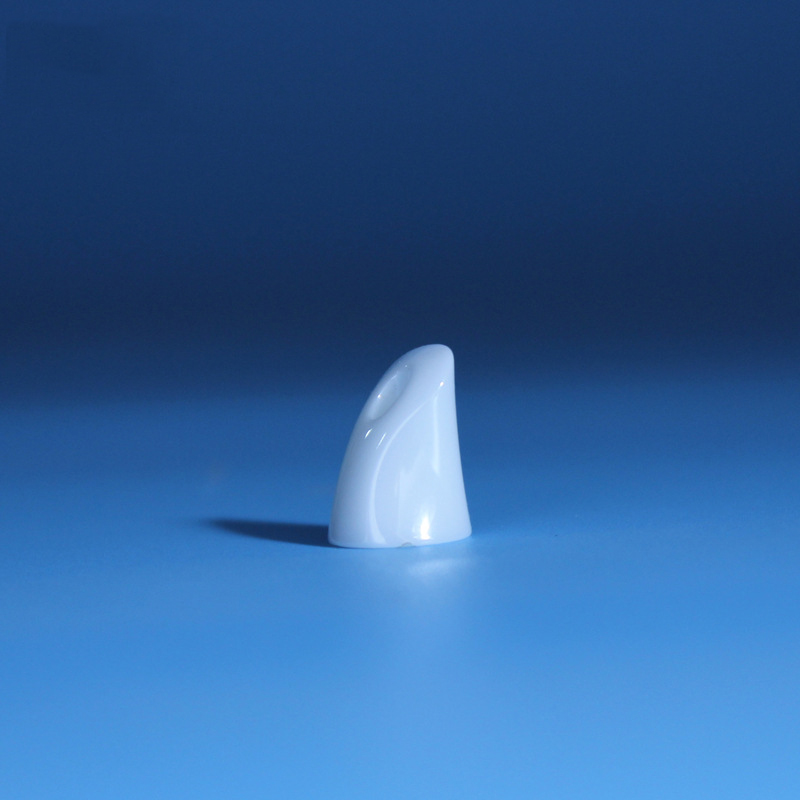

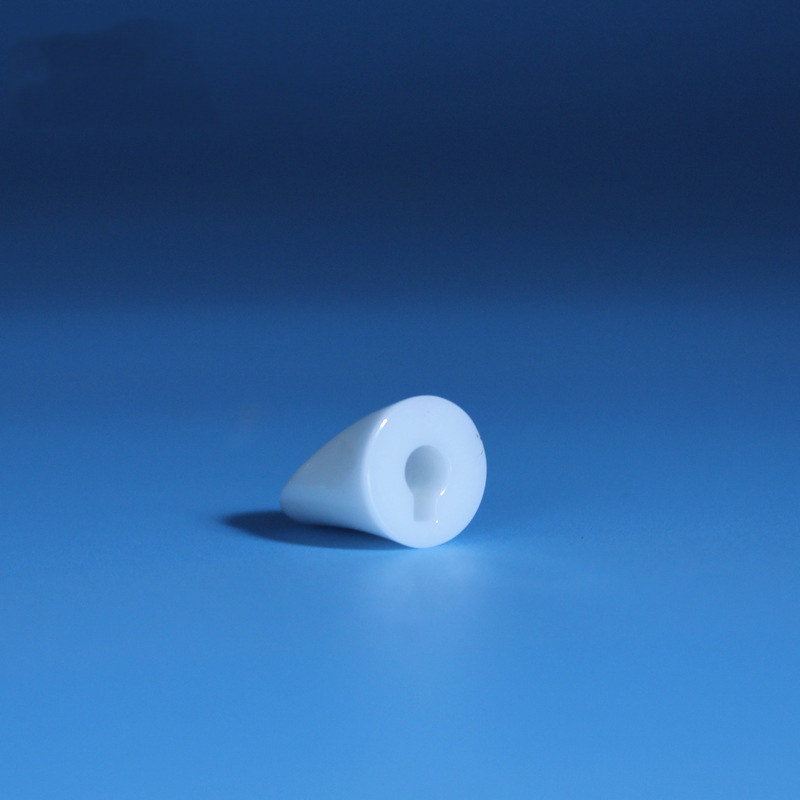

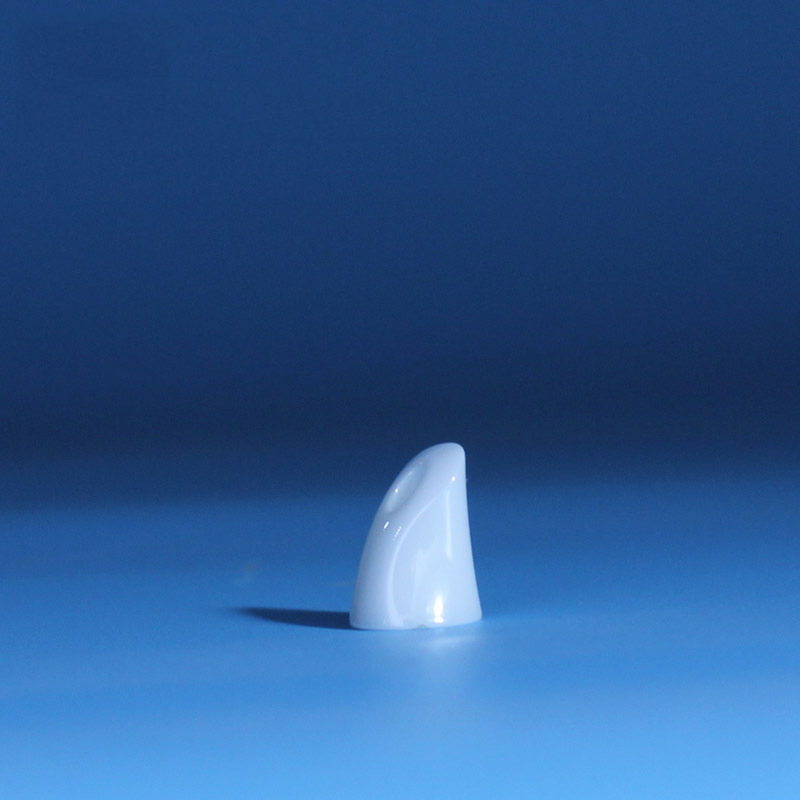

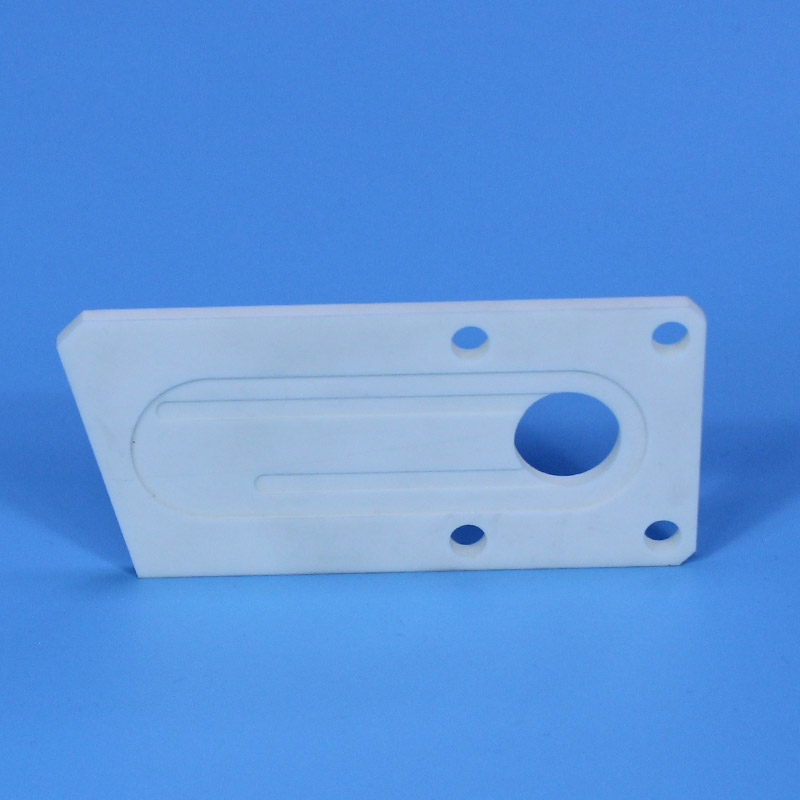

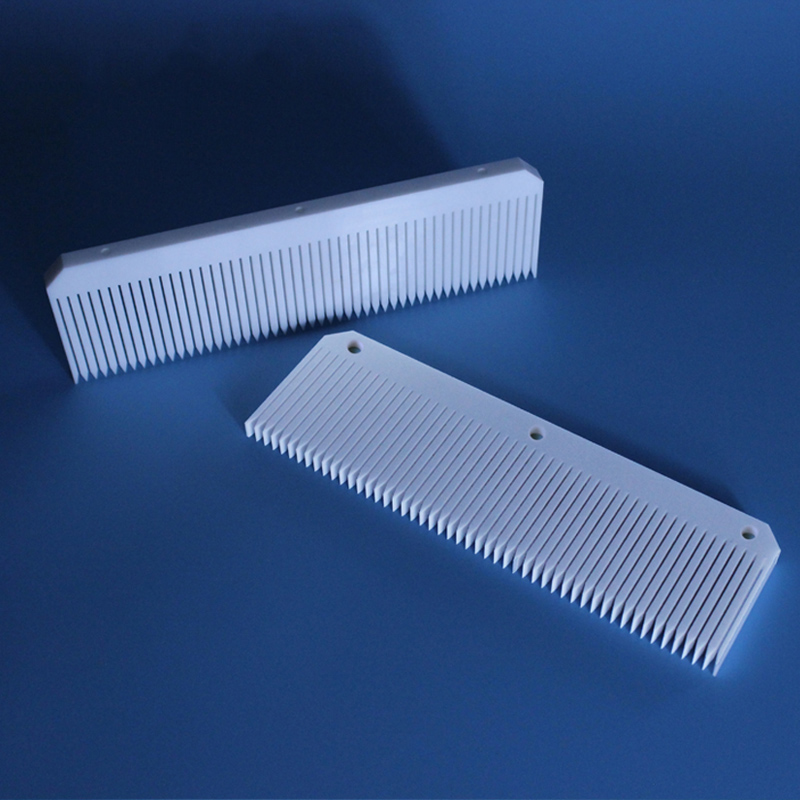

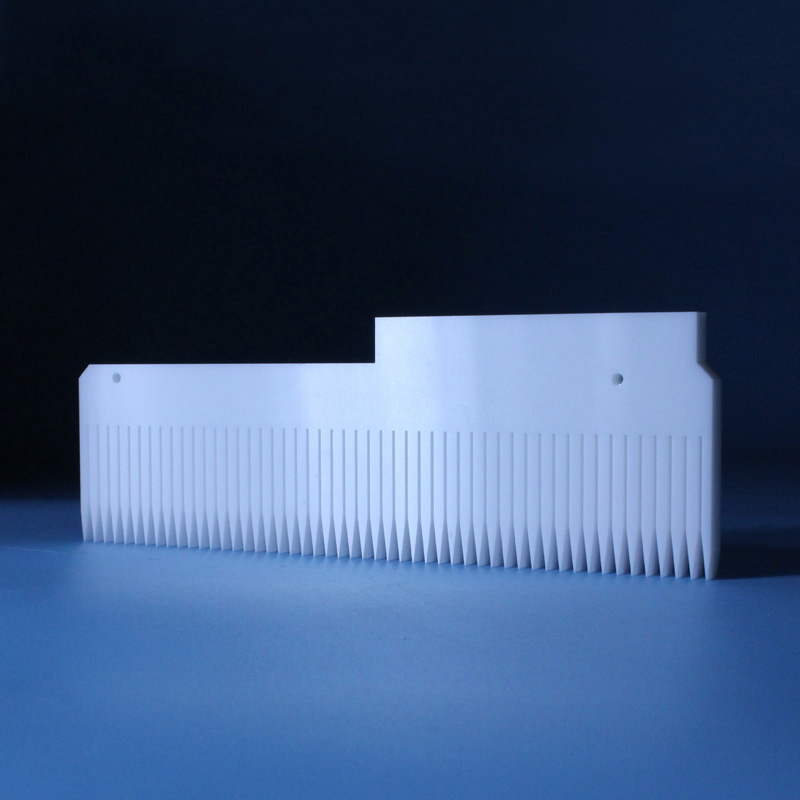

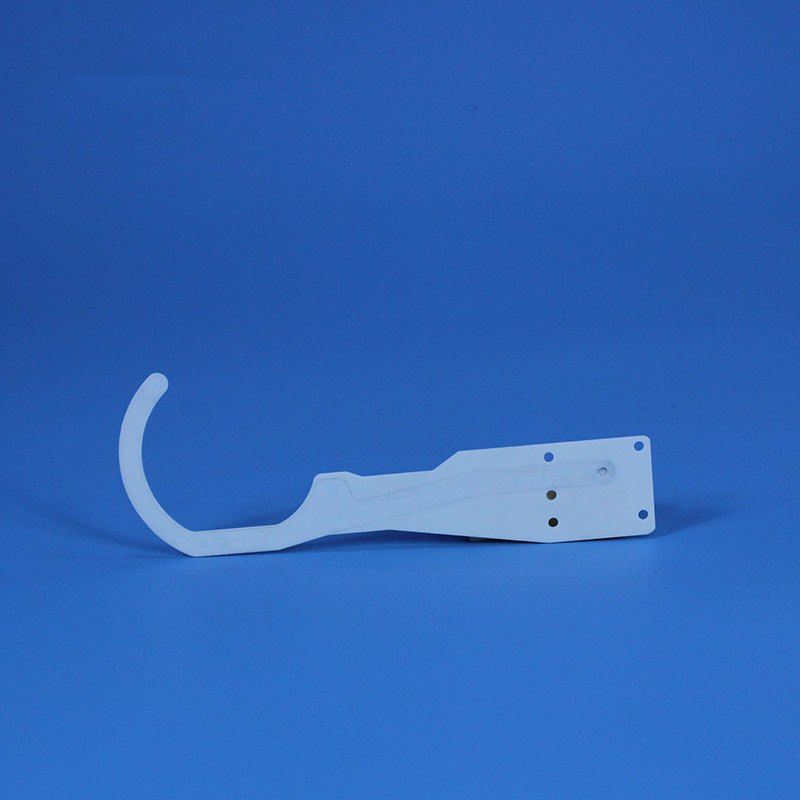

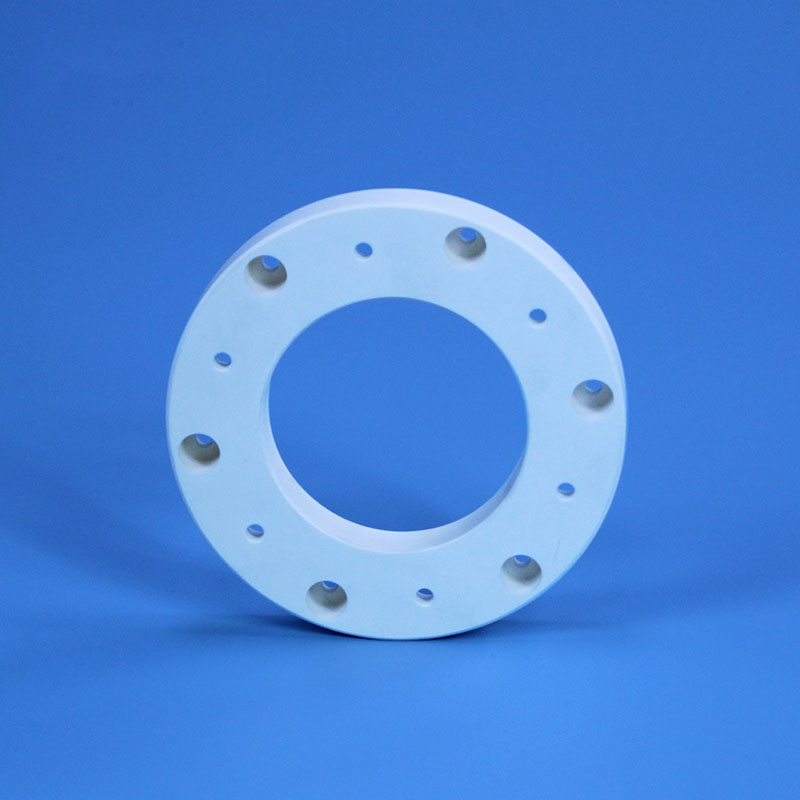

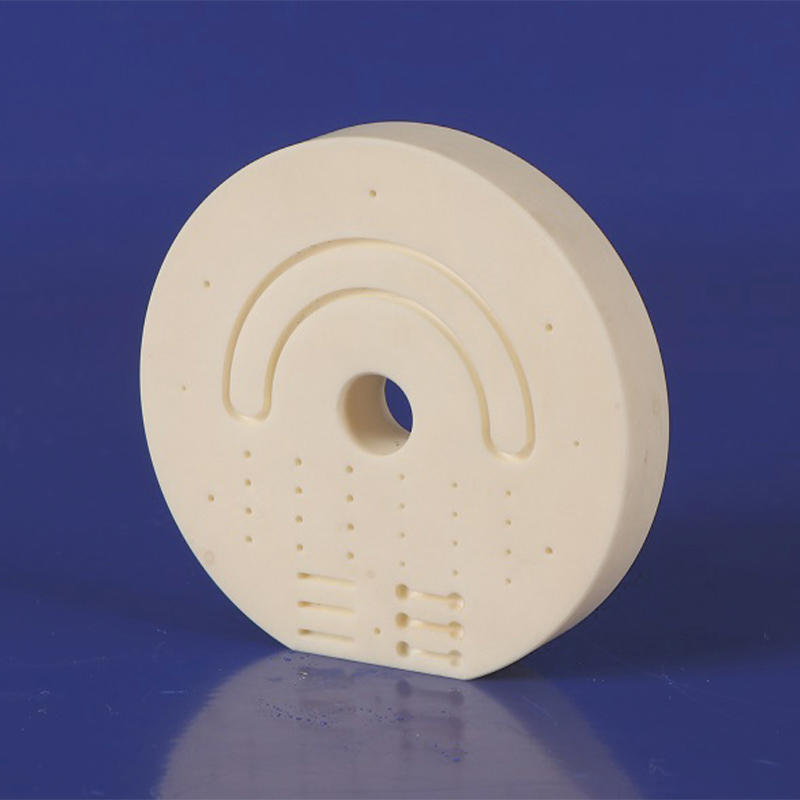

Zirconia Ceramic Injection Parts

Ceramic injection molded parts are a relatively common molding process in the production of special ceramics. Huamin Ceramics has a professional ceramic injection molding team that can provide users with precision injection molded parts of a variety of ceramic materials. This product is a zirconia ceramic injection nozzle on the shampoo bottle. It has a jade-like texture and is very suitable for use as an accessory for high-end products. Our ceramic injection molded parts include: oxide ceramic injection molded parts, alumina ceramic injection molded parts, silicon nitride ceramic injection molded parts, etc., which can fully meet the special requirements of different accessories.

Ceramic Encyclopedia:

The production and processing technology of special ceramics has been continuously developing and changing in recent decades. In the first 30 years, CIM occupies a small part of the vast ceramic industry, and the major progress made in its commercial vitality mainly began with the contribution of research and development in the 1970s and 1980s. In the 1980s, with the need for the development of ceramic engines and the preparation of complex-shaped ceramic thermomechanical components such as turbine rotors and blades, the American Bettel Memorial Association organized nearly forty university research institutions and companies in the world to formulate " "Ceramic injection molding" research and development program, injection molding provides an efficient manufacturing process for these parts. This process has continued to the present, and has become a mature ceramic molding process-ceramic injection molding process.

With the development of optical communications at the beginning of this century, the demand for zirconia ceramic ferrules and sleeves for optical fiber connectors, biomedical ceramics, electronic devices, precision machinery, ceramic watches, and recently developed ceramic exterior parts for mobile phones and smart wearable devices has further promoted The research and application of ceramic powder injection molding are discussed.

Huamin Ceramics has a professional injection ceramic processing workshop and complete sets of equipment, which can provide users with a series of services from mold design to molding and sintering.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Zirconia ceramic circular ring