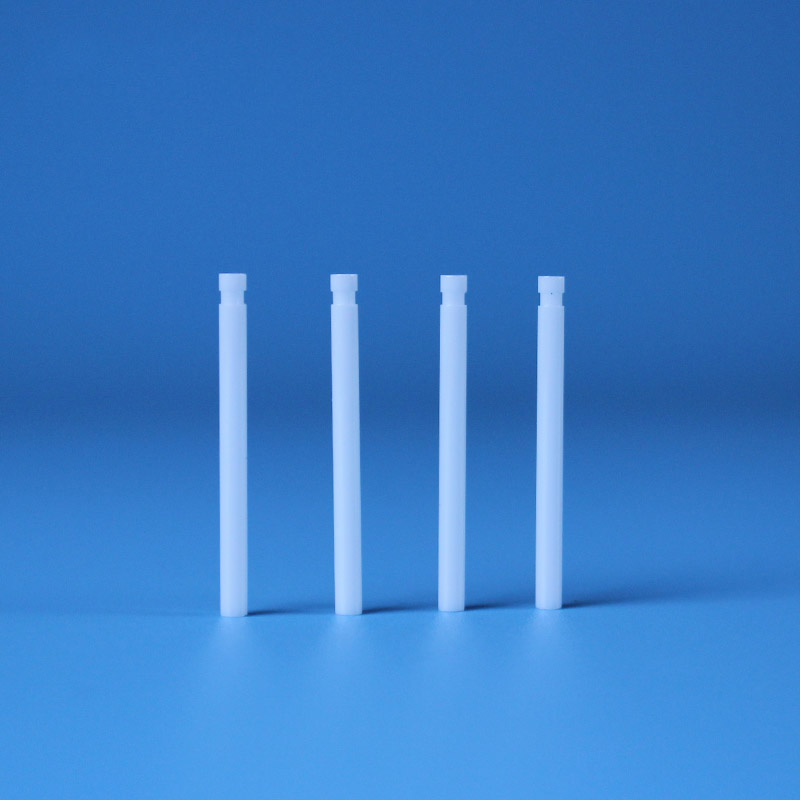

Zirconia ceramic plungers are used as one of the high quality, reliable components in reciprocating pumps in the petroleum, industrial manufacturing and food processing industries. Our expert manufacturing process eliminates the risk of pull-off problems that often occur with ceramic plungers and enables us to provide strong, reliable components that last for years.

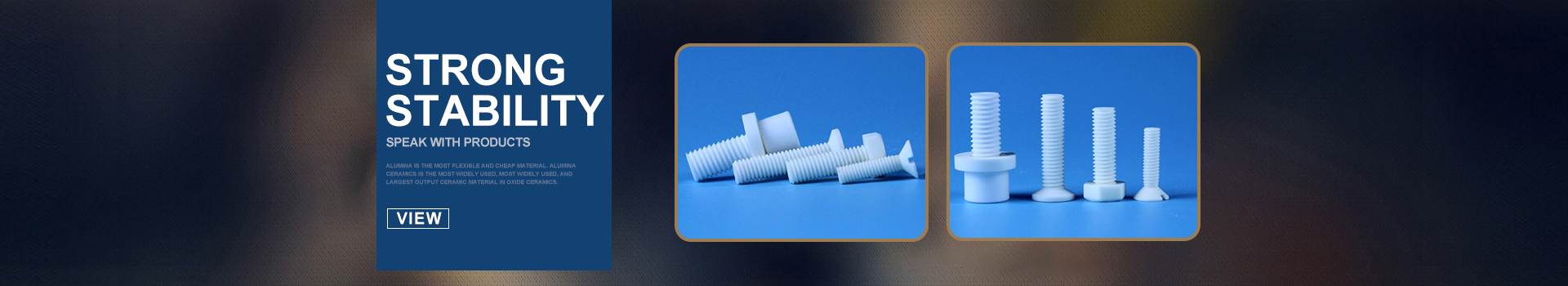

The ceramic plunger sets itself apart from the competition with a unique advantage: a two-part epoxy adhesive secures the ceramic surface to a metal adapter that screws into the pump. Adhesives are mixed using a special formulation and allowed to cure longer. No ceramic plunger has a perfectly concentric inner diameter, but we can machine a shaft to make it a perfect fit;

This proprietary process allows them to produce ceramic pump plungers of superior quality and reliability. The binder in a low quality plunger will not hold over time, causing the ceramic part to separate from the metal piece. This will break the barrel and damage the pump;

Not only are the ceramic plungers made with a particularly resilient adhesive, but both sides of the plunger are thoroughly cleaned before use to remove any contamination and enhance adhesion. These two features virtually eliminate the risk of pulling apart;

All plungers are manufactured to inspection-confirmed tolerances. After production and inspection, the product goes through an additional quality assurance process to ensure that the metal and interior of the plunger are clean and ready for immediate use.