The current application of alumina ceramics is more and more extensive, and the market demand is also increasing, so now there are more and more alumina ceramic manufacturers, so how to choose alumina ceramic manufacturers? The following is an analysis for you.

1.Exquisite craftsmanship

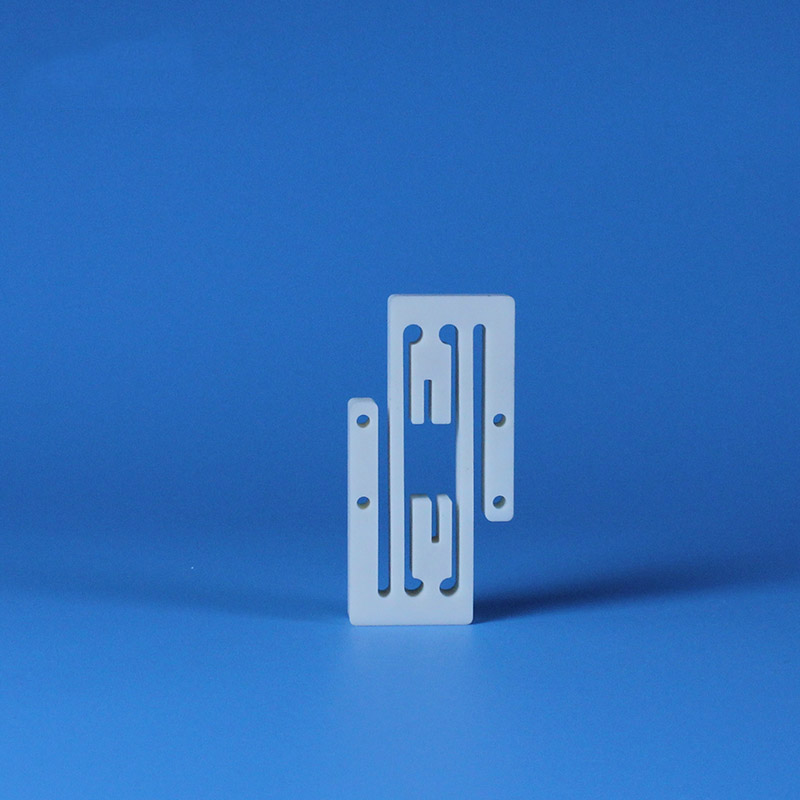

Only ready-made equipment is not enough to guarantee the product quality of alumina ceramics 100%. It should also have supporting production technology. Therefore, whether the production technology of alumina ceramics is exquisite is another key point that enterprises need to pay attention to when choosing manufacturers. Only with good craftsmanship can we produce ceramic products with excellent wear resistance, corrosion resistance, high temperature resistance, acid and alkali resistance and other properties, which can reach the international advanced level.

2.Raw material quality

In addition to good equipment and good technology, if you want to produce better quality alumina ceramics, you should also pay attention to the selection of raw materials. When choosing a manufacturer, an enterprise should know what materials the manufacturer uses, and try to choose engineering ceramics. material manufacturers, because this ceramic material has higher hardness and better wear resistance.

3.High-precision equipment

Because the processing difficulty of alumina ceramics is extremely high, the requirements for equipment are extremely high, and imported equipment with very high precision is required, and such equipment is also relatively expensive in terms of input cost, so not every manufacturer will have it. Therefore, When choosing a manufacturer of alumina ceramics, it is best for enterprises to visit the factory to find out if they use high-precision equipment.