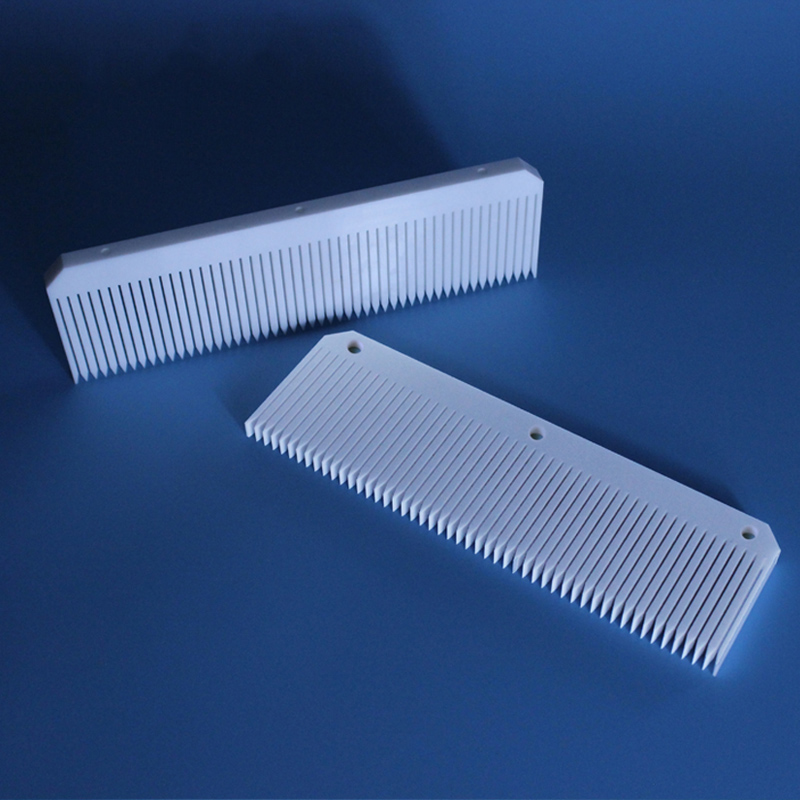

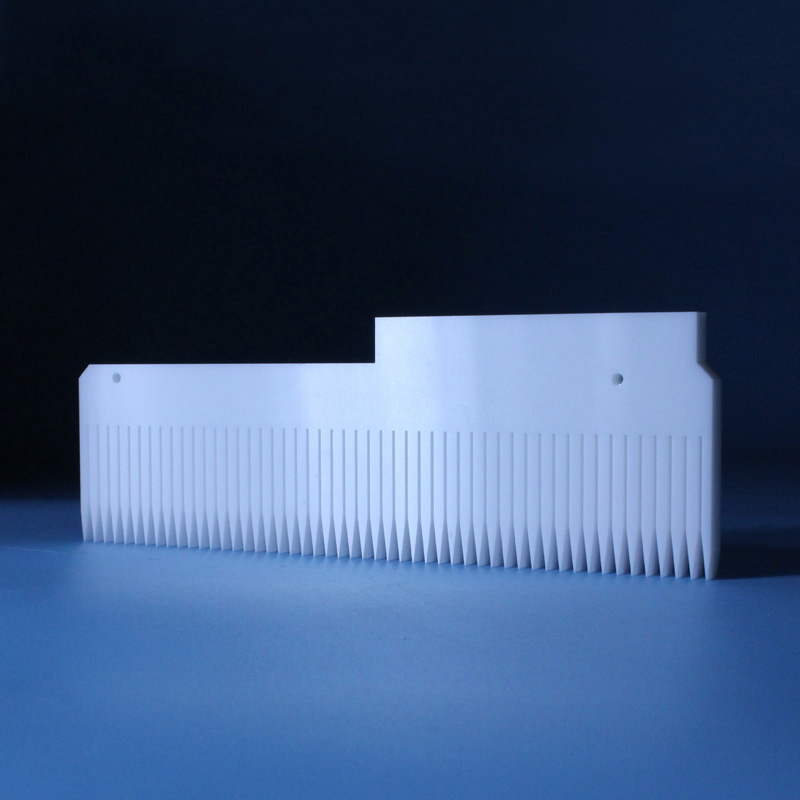

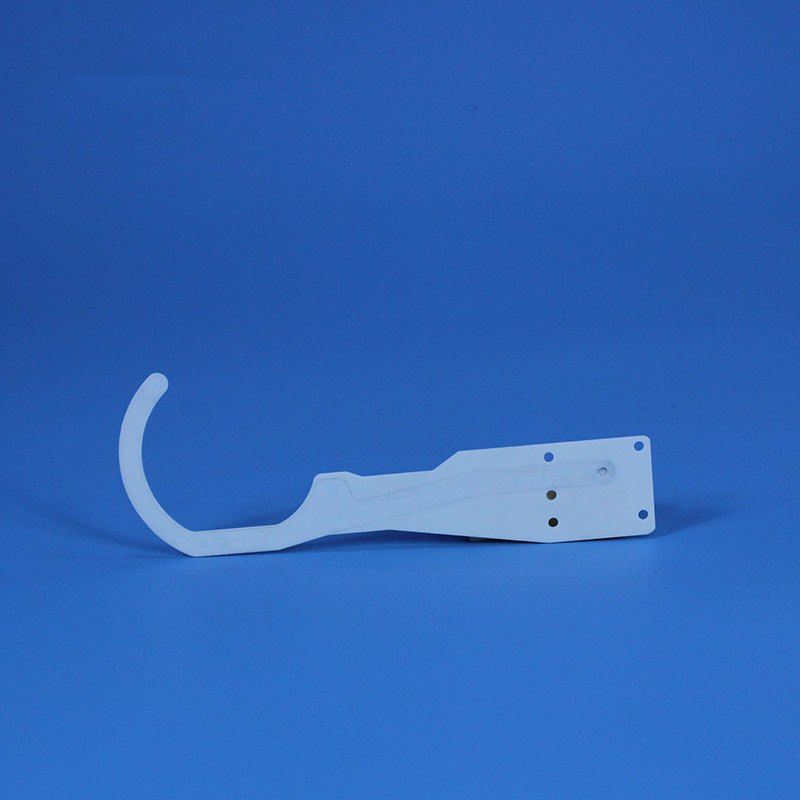

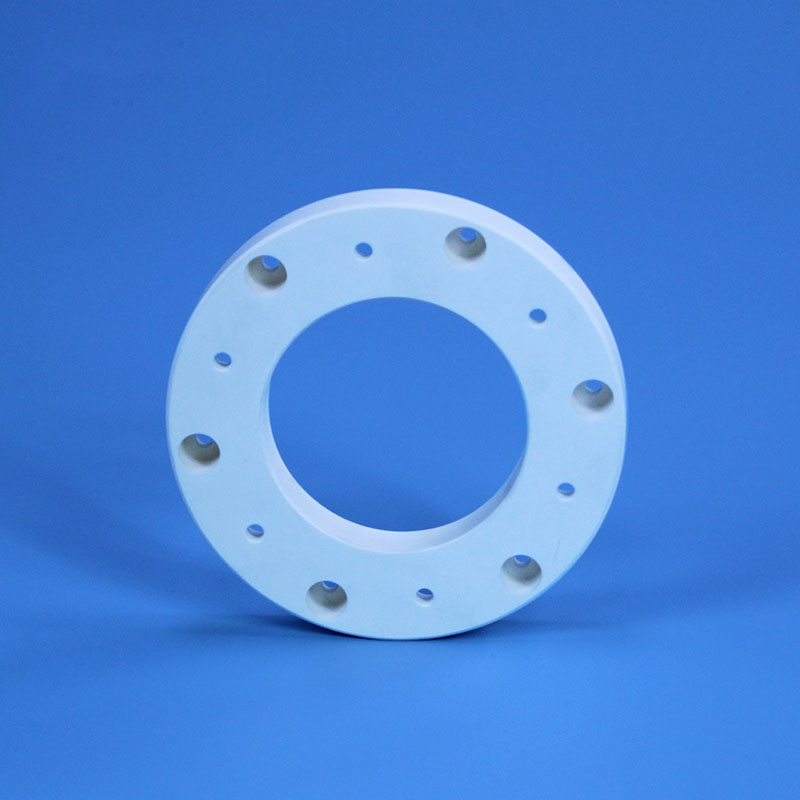

Products

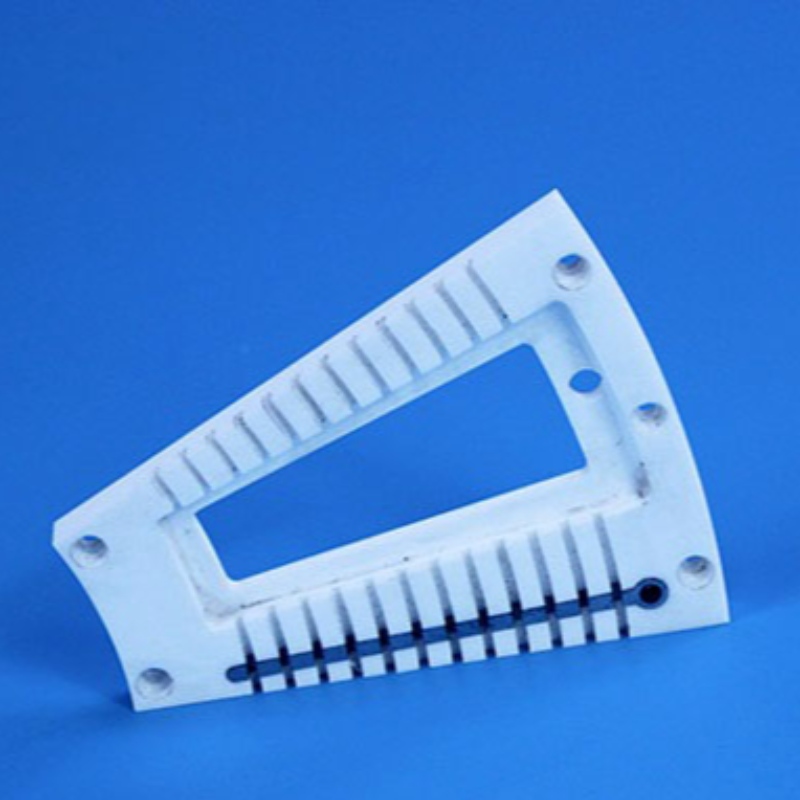

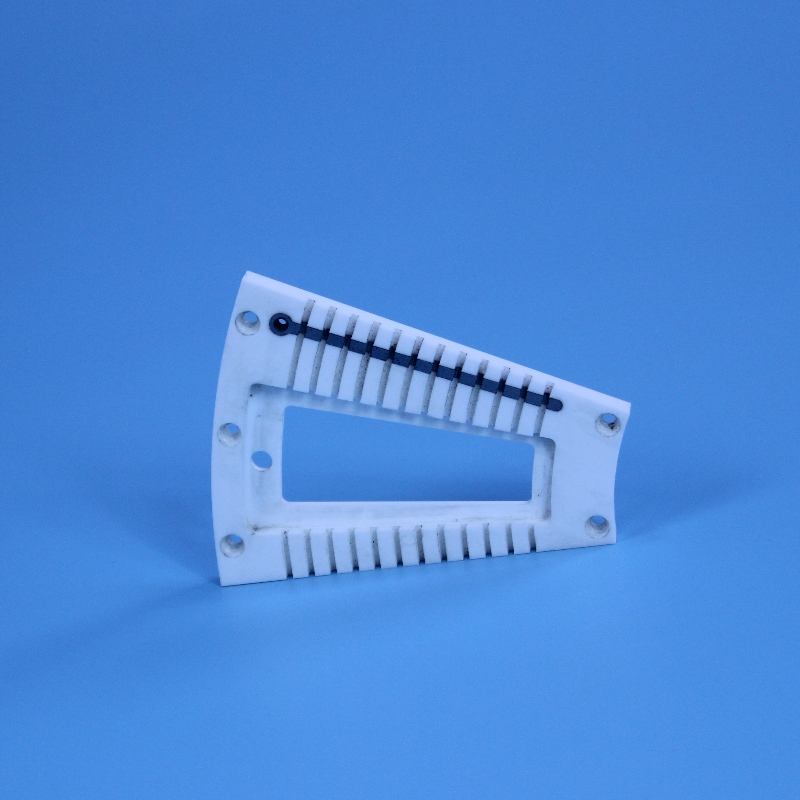

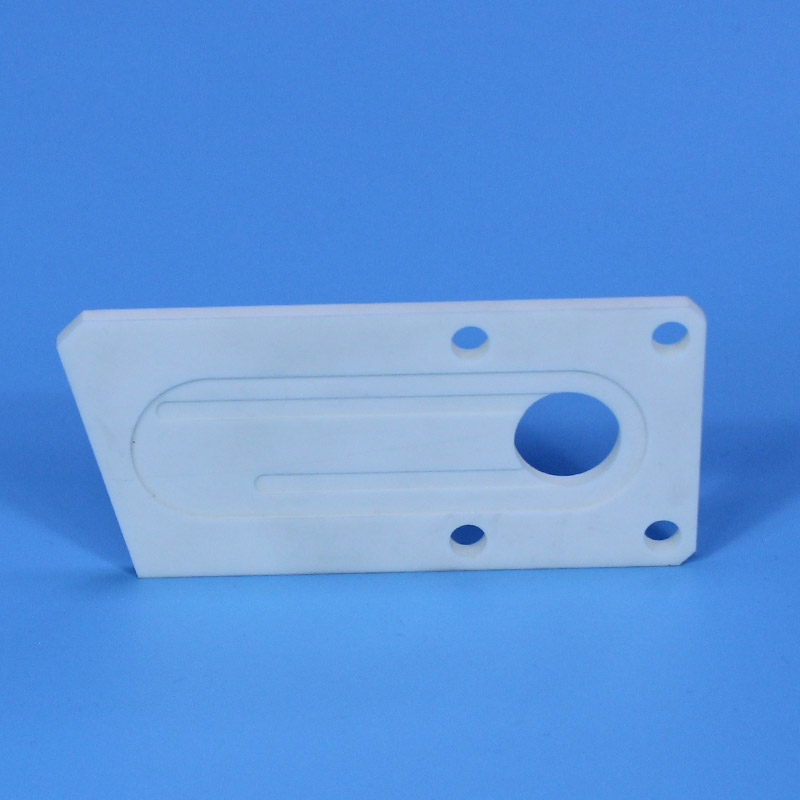

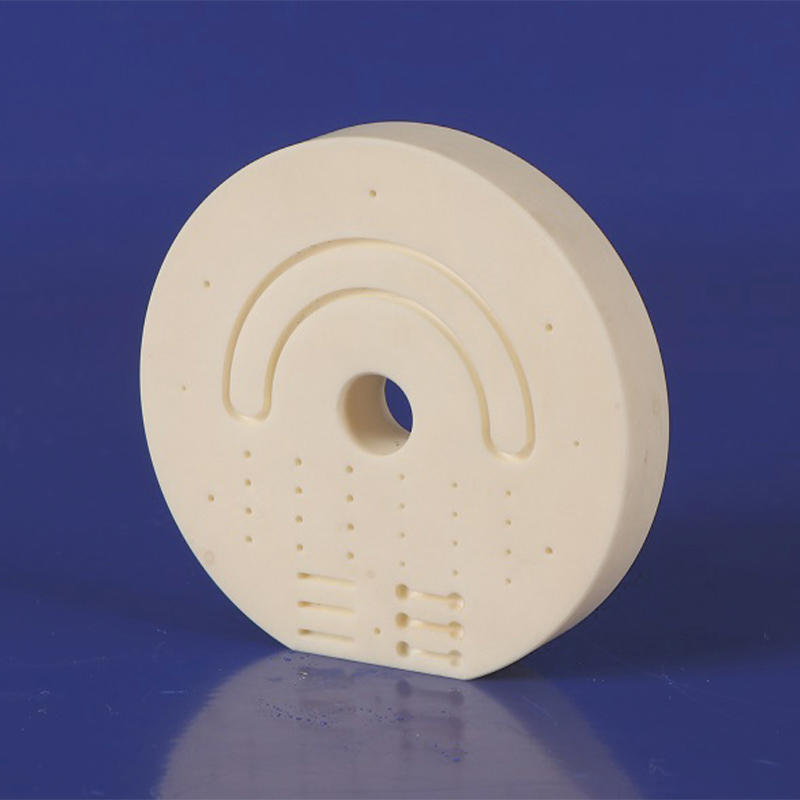

Alumina ceramic fixing bracket

Five Advantages Of Products

- Highly purified ceramic raw materials

- Accept product customization according to customer needs

- Fully equipped and exquisite technology: sintering, static pressing, grinding, polishing, finishing, etc.

- Provide mature processing solutions

- Superior performance, quality and quantity, precision machining

Product Details

Alumina ceramic fixing bracket Al2O3 ceramics is currently one of the most studied and widely used materials among new materials. In terms of electronics and electricity, there are various Al2O3 ceramic base plates, substrates, ceramic membranes, transparent ceramics and various Al2O3 ceramic electrical appliances. Insulating ceramic parts, electronic materials, magnetic materials, etc., among which Al2O3 transparent ceramics and substrates are the most widely used. It is also widely used in other high-tech fields, such as aerospace, high-temperature industrial furnaces, composite reinforcement and other fields.

Ceramic Encyclopedia:

The molding methods of alumina ceramics mainly include grouting, hot die casting, film rolling, dry pressing, isostatic pressing, casting, injection and gel injection molding, etc. Different molding methods correspond to different processes, and the raw materials for hot die casting and rolling film The processing method is mainly dry grinding, and the raw material processing methods of grouting, dry pressing and isostatic pressing are mainly wet grinding. Alumina ceramics is a general term for ceramic products made of calcined alumina as the main raw material. Due to the different content of alumina, it is divided into 75 porcelain, 85 porcelain, 90 porcelain, 95 porcelain, 97 porcelain and 99 porcelain. The main raw material, calcined alumina, is mainly made from industrial alumina, aluminum hydroxide or boehmite, which is calcined at 1300-1500°C. The raw material processing methods of alumina ceramics are mainly dry and wet. The dry method is mainly dry grinding by a roller ball mill, and the wet method is mainly wet grinding by a roller ball mill, agitating mill, and a sand mill.

Dongguan Huamin Ceramic Technology Co., Ltd

Contact Person: Bao Dunhua

Department: Sales Department

Post: manager

Telephone: 86-176-7451-1727

Landline: +86-136-9173-1390

Company Address: Room 106, unit 2, building 1, No. 17, headquarters 2nd Road, Songshanhu Park, Dongguan City, Guangdong Province

Factory Address: Rhinoceros, Dalang Town, Dongguan City

Website: huaminceramics.us764.com

Previous: Alumina ceramic crucible holder

Next: Alumina ceramic arm