Alumina ceramics may be relatively unfamiliar to many people in the field of metal processing, but for our friends in the ceramic industry, they are already familiar and can no longer be familiar. Alumina ceramics have relatively excellent thermal conductivity and high temperature resistance. At present, it has been widely used in various fields, and its characteristics have been studied more thoroughly. Let's take a look at some of the basic uses of alumina ceramics and the physical properties of this material.

Characteristics of alumina ceramic materials

One, light weight

Generally speaking, the density of ceramic materials is not high. The same is true for alumina ceramics. Its density is only 3.5g/cm3, which is only 50% of iron. After aluminum, its weight will be greatly reduced (of course, due to the high brittleness of aluminum oxide, it is not suitable for all places).

Second, the hardness is large

In the ceramics field, the hardness of alumina is medium, and its Rockwell hardness is HRA80-90. Although not as hard as silicon carbide and silicon carbide, it is much harder than cemented carbide and stainless steel. This is also an important reason why it is selected as a wear-resistant part.

Three, good wear resistance

Measured by the Institute of Powder Metallurgy of Central South University, the wear resistance of alumina ceramics is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. According to our customer follow-up investigation over the past ten years, under the same working conditions, the service life of the equipment can be extended by at least ten times.

Strengthening process for the use of alumina ceramics:

Four, other performance

People are always discovering new materials and researching new processes, and the same is true for ceramics. After years of development, people are not satisfied with the existing properties of alumina. In order to strengthen alumina ceramics and significantly improve its mechanical strength, recently a new alumina ceramic strengthening process has been introduced abroad. The process is novel and simple. The technical method adopted is on the surface of alumina ceramics, using electron beam vacuum coating, sputtering vacuum coating or chemical vapor deposition method, and coating a layer of silicon compound film at 1200℃~1580℃ The lower heating treatment can toughen the alumina ceramics.

The use of alumina ceramics:

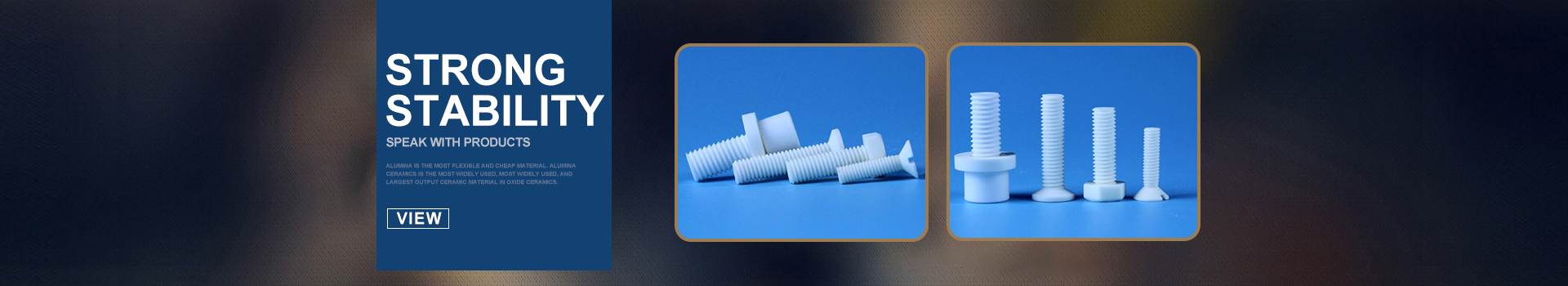

Because the material has the characteristics of low thermal expansion, corrosion resistance, high thermal conductivity, good insulation, high mechanical strength and good wear resistance. Therefore, it is often used to resist the corrosion of gold and slag. In addition, it can also be used as refractory materials, wear-resistant parts on mechanical equipment, and tool materials. In addition, in the field of electronic ceramics, many alumina ceramics are also used as insulators. In addition, many of the valves, ceramic tubes, ceramic screws, etc. of taps can be made of alumina. Generally speaking, as people's understanding of this material continues to deepen, its application becomes more and more widespread, and the natural price is lower and lower.