MACOR® Machinable Glass Ceramics is a globally recognized major technological innovation, as well as a technical solution with a wide range of industrial applications. Open up a wide range of possibilities MACOR® gives the performance of technical ceramics and the versatility of high-performance polymers, while providing the workability of soft metals. Therefore, MACOR® is an excellent engineering material that can be quickly designed into highly complex shapes using traditional metal processing tools.

Performance attributes

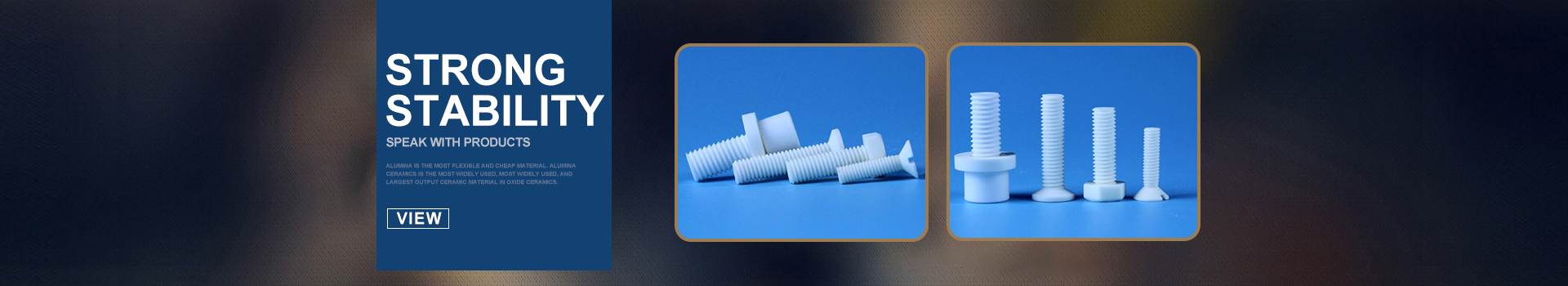

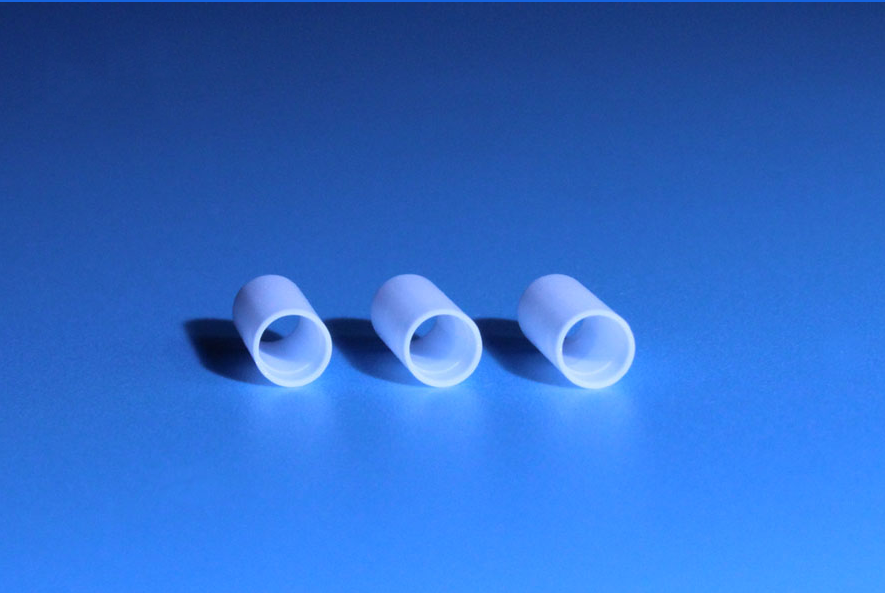

It is a white, non-wetting, odorless, non-porous and non-venting material.

MACOR® has very small machining tolerances and has very good machinability.

Convenient for complex shape design. (The size tolerance is less than +/-0.013mm,

It can be processed to a surface flatness of less than 0.5µm,

Polished to a surface finish of less than 0.013µm)

MACOR® can continue to be stable when the temperature is 800°C. Under no-load conditions,

Peak at a temperature of 1000°C

And it will not creep or deform like ductile materials.

The coefficient of thermal expansion of MACOR® is easily matched to most metals

Convenient for sealing glass.

Especially at high temperatures, as an electrical insulator,

It has the advantages of high voltage and wide frequency spectrum.

Low thermal conductivity

No sintering required

Can be coated with a variety of materials

Application field

The ultra-high vacuum environment Macor is used as an insulator or coil support and a vacuum feed tank. In these applications, the conductive material is supported by the Macor component, and compatible sealing glass is used to create a hermetic seal that is vacuum tight.

Macor parts can be used in gaskets, connectors and windows for microwave tube equipment, and can also be used as sample holders in on-site ion microscopes.

Aerospace components

Welding nozzle

Medical equipment

Lamps

Advantage

Easy to process, high temperature resistance, low thermal conductivity, keep small tolerances, electrical insulator, non-porous, non-venting, strong and hard, highly polishable, brazing a variety of materials, anti-radiation, lead-free, constant and super High vacuum environment, laser technology, semiconductor/electronics, aerospace, chemical industry, automotive industry, military, nuclear industry...etc.

The unique material of Macor processable glass ceramics combines the performance of technical ceramics with the versatility of advanced polymers, providing value-added opportunities for many industries. Macor Machinable Glass Ceramics is an excellent engineering solution that can meet most technical material requirements quickly, accurately and economically.